J.H. Williams, The SuperCompany

-

What's New (Last Updated July 8, 2025)

Recent changes to this page:

- 07/08/2025: Updated catalog table, minor layout changes, added a

Williams S-140A 1/2-Drive Universal.

- 07/07/2025: Added a

Williams S-41A 1/2-Drive 17 Inch Flex Handle.

- 07/03/2025: Added

Williams ST-12xx 1/2-Drive Sockets from WSS-5 Set.

- 07/02/2025: Minor updates to menus, added a

Williams WSS-5 1/2-Drive Socket Set.

- 06/26/2025: Updated catalog table.

- 06/17/2025: Updated catalog table.

- 06/13/2025: Added 1943 catalog A-409 to table.

- 02/19/2025: Minor layout changes.

- 12/30/2024: Minor reorg of automotive specialty tools, minor layout changes.

- 12/29/2024: Minor layout changes, added a

Williams 1731BR 3/4x7/8 Brake Wrench,

updated photo for

Williams A1039C 1-3/8x1-7/16 Open-End Wrench.

- 11/30/2024: Minor layout changes.

- 11/19/2024: Added a

1949 Catalog Listing for Williams R-19A Refrigeration Socket Set.

- 11/17/2024: Minor layout changes.

- 09/02/2024: Added a

Rare Williams 1232A 1-1/32 Single-Open Waterpump Wrench.

- 05/26/2024: Minor layout changes.

- 05/17/2024: Minor layout changes.

- 04/16/2024: Added a

Williams Early 1725B 1/2x19/32 Open-End Wrench.

- 04/12/2024: Minor layout changes.

- 01/29/2024: Move section on "Volume" line.

- 01/28/2024: Fixed bitrot, minor layout changes.

- 09/17/2023: Added a

1928 Notice for Williams-Husky Wrench Set.

- 07/27/2023: Added no-wrap spans for figures, fixed bitrot, minor layout changes.

- 07/26/2023: Minor layout changes, more work needed.

- 07/13/2023: Minor layout changes.

- 07/05/2023: Added links to ITCL in catalog table.

- 04/10/2023: Minor layout changes.

- 03/26/2023: Minor layout changes, use Unicode symbol ⬡ for [HEX]C size notation.

- 03/25/2023: Updated section on early Superrench production,

added a Williams Early 1025 1/2x19/32 Open-End Wrench.

- 03/18/2023: Added index entry for Crescent Tool production for Williams.

- 03/17/2023: Added link to ITCL for 1901 catalog.

- 03/09/2023: Updated photo for

Williams 1085 1x1-1/8 "S"-Shaped Wrench.

- 01/21/2023: Updated catalog table to add links to ITCL.

- 12/23/2022: Fixed some bitrot, improved indexing.

- 03/06/2022: Added more examples of contract production.

- 03/02/2022: Reorganized section for "Volume" secondary brand, added a

1939 Catalog Listing for Williams "Volume" Wrenches.

- 03/01/2022: Minor updates to history.

- 02/28/2022: Updates to Williams/Husky history, added a

1929 Ad for Williams "Volume" Wrenches.

- 02/27/2022: Updates to catalog table.

- 02/26/2022: Minor updates to index catalog listings.

- 02/25/2022: Added "VOLUME" trademark, added a

1933 Catalog Listing of Williams S-51 Ratchet.

- 02/24/2022: Renumbered figures, updated section on tappet wrenches, added a

1940 Ad for Williams Wrenches and Socket Tools and a

1927 Catalog Listing of Williams Tappet Wrenches.

- 02/23/2022: More updates to history, added a

1927 Catalog Listing of Williams Obstruction Wrenches.

- 02/22/2022: Added a 1901 Catalog Listing of Williams Engineers' Wrenches.

- 02/21/2022: Updated history and trademark tables.

- 02/20/2022: Updated patent and trademark tables.

- 01/22/2022: Added Chanslor & Lyon to distributor list.

- 01/01/2022: Added a 1910 Notice for Williams Vulcan Auto Tool and a

1968 Catalog Description of Impact Extruded Sockets.

- 05/21/2021: Added a

Williams 725B 1/2x9/16 Open-End Wrench.

- 05/03/2021: Added a

Williams No. 8105 Single-Offset Box Wrench Set.

- 04/11/2021: Added earlier "Vulcan" trademarks.

- 04/10/2021: Added "Bantam" and "Midget" trademarks, issued 11/11/1930.

- 07/01/2019: Added

a Williams BP-3 3/8-Drive Phillips Driver.

- 06/07/2019: Added

a Williams B-115 3/8-Drive 10 Inch Extension,

a Williams B-140 3/8-Drive Universal,

and Williams B-12xx 3/8-Drive Sockets.

- 06/06/2019: Added

a Williams B-51 3/8-Drive Reversible Ratchet.

- 06/05/2019: Added

a Catalog Listing for Williams S-320 Socket Set

and a Williams F-15 3/8-Drive Speeder.

- 06/04/2019: Added a

Williams B-315 3/8-Drive Socket Set.

- 05/23/2019: Added a

Williams BD-814 3/8-Drive 7/16 8-Point Deep Socket

and

Williams BU-12xx 3/8-Drive Universal Sockets.

- 05/22/2019: Added a

Williams 1034 7/8x1-1/16 Open-End Wrench.

- 05/21/2019: Added a

Williams B-110 3/8-Drive 5.5 Inch Extension

and

Williams BP-2 and BP-3 3/8-Drive Phillips Drivers.

- 05/20/2019: Added a catalog listing for WSB-6D set, added a

Williams B-115 3/8-Drive Extension.

- 05/19/2019: Added a

Williams B-108 3/8-Drive Extension,

a Williams B-140A 3/8-Drive Universal,

a Williams WSB-6D 3/8-Drive Socket Set,

and Williams B-12xx 3/8-Drive Sockets.

- 05/18/2019: Added a

Williams 7033C 15/16x1 Box Wrench.

- 05/17/2019: Added a

Williams NM-20A 1/4-Drive Sliding Tee Handle

and a

Williams 8034 7/8x1-1/16 Offset Box Wrench.

- 05/16/2019: Minor tweaks to layout, added a

Williams No. 1285P 1/4-Drive Socket Set

and a

Williams 7039 1-1/4x1-7/16 Duohex-Box Wrench.

- 04/21/2019: Pages updated for responsive design.

- 04/02/2019: Added

Williams 1/4-Drive Sockets from No. 1269 Set.

- 04/01/2019: Minor reorganization, renumbered figures.

- 03/31/2019: Added a

Williams No. 1269 1/4-Drive Socket Set and a

Williams ST-1232 1/2-Drive Socket.

- 03/30/2019: Added

Williams 9/32-Drive Sockets from M-310 Set.

- 03/28/2019: Added

Williams 5/16-Hex Drive Sockets from No. 287 Set

and a

Williams No. 1288P 9/32-Drive Socket Set.

- 03/27/2019: Major reorganization of sections, added a

Williams-Husky No. 287 Socket Set,

a Placeholder for Williams 1269 Socket Set,

and

Williams No. 1519 Ignition Pliers.

- 03/26/2019: Added a

Williams 1128 7/16x7/16 Ignition Wrench

and a

Williams 1108A 1/4x5/16 Ignition Wrench.

- 03/25/2019: Reorganized 1/4-drive section, added a

Williams 1112 3/16x3/16 Ignition Wrench,

a Williams NM-20A 1/4-Drive Sliding Tee Handle,

and Williams No. 1519 Ignition Pliers.

- 03/24/2019: Added a

Williams 1120 5/16x5/16 Ignition Wrench and a

Williams 1122 11/32x11/32 Ignition Wrench.

- 03/23/2019: Added a

Williams 1118 9/32x9/32 Ignition Wrench,

a Williams 1132 1/2x1/2 Ignition Wrench,

and a Catalog Listing for Williams B-315 Set.

- 01/26/2019: Added a

Williams 7033C Box Wrench.

- 01/25/2019: Added a

Williams 7034A Duohex-Box Wrench.

- 01/24/2019: Added a catalog listing of "Volume" wrenches.

- 01/31/2016: Added a

Williams 1162 Combination Wrench.

- 01/27/2016: Added a

Williams 1124 Ignition Wrench.

- 01/18/2016: Added a

Williams 1040 Open-End Wrench.

- 01/15/2016: Added a

Williams 9725B Offset Box Wrench.

- 01/11/2016: Added a Williams 4731A Box Wrench.

- 01/08/2016: Added a Williams 1090 Tappet Wrench.

- 01/05/2016: Added a

Williams 1520 Waterpump Pliers.

- 01/03/2016: Added a Williams 83B S-Shaped Open-End Wrench.

- 01/01/2016: Added a Williams 7033C Duohex-Box Wrench.

- 12/30/2015: Added a Williams 1990 Brake Wrench.

- 12/29/2015: Reorganized discussion of manufacturing dates.

- 12/28/2015: Added a Williams 92 Tappet Wrench.

- 12/26/2015: Added a

Williams 1737 Open-End Wrench.

- 12/11/2015: Added a

Williams A1725 Ribbed-Style Open-End Wrench.

- 12/10/2015: Added a

Williams 990 Brake Adjustment Wrench.

- 12/04/2015: Added a Williams 1094 Tappet Wrench.

- 11/17/2015: Minor reorganization.

- 01/24/2012: Added a

Williams 1122 Ignition Wrench.

- 01/04/2012: Added a

Williams 7727 Transitional Duohex-Box Wrench.

- 12/21/2011: Added a

Chrome-Alloy (Williams) 18733C Offset Box Wrench.

- 12/15/2011: Added a

Williams 7731A Transitional Duohex-Box Wrench.

- 12/14/2011: Added a

Williams A1733 Ribbed-Style Open-End Wrench.

- 12/13/2011: Added a

Williams 8030 Paneled Offset Box-End Wrench.

- 12/12/2011: Added a

Williams 1035 Ribbed-Style Open-End Wrench.

- 12/11/2011: Added a Williams 8729 Offset Box Wrench.

- 12/06/2011: Added a

Williams A1729 Ribbed-Style Open-End Wrench.

- 12/02/2011: Added a

Williams 9725B Short Offset Box-End Wrench.

- 11/26/2011: Added a Williams 1736A Open-End Wrench.

- 11/19/2011: Added a Williams A1723 Open-End Wrench.

- 11/02/2011: Added a Williams 1322 Open-Flare Wrench.

- 10/10/2011: Added a Williams 8940 Water-Pump Wrench.

- 09/05/2011: Added a

Williams A1735 Ribbed-Style Open-End Wrench.

- 08/28/2011: Added a Williams 2727 Obstruction Wrench.

- 07/31/2011: Added a Williams A1029 Ribbed-Style Open-End Wrench.

- 06/19/2011: Added a Cromal 19723 Short Offset Box Wrench.

- 06/12/2011: Added a Williams 7723 Paneled Box-End Wrench.

- 06/10/2011: Added a Williams 2031 Obstruction Wrench.

- 06/07/2011: Added Williams PL-6 Combination Pliers.

- 06/04/2011: Added a Williams 1164 Combination Wrench.

- 05/29/2011: Added a Williams 8942 Water-Pump Wrench.

- 05/06/2011: Added a Williams 1033 Open-End Wrench.

- 04/27/2011: Added a

Williams Early 1033C Open-End Wrench.

- 04/24/2011: Added a

Williams A1033A Ribbed-Style Open-End Wrench.

- 04/19/2011: Added a Williams F-50A Refrigeration Ratchet.

- 04/16/2011: Added a Williams NX-50 1 Inch Hex Drive Ratchet

and a Williams R-19A Refrigeration Socket set.

- 04/11/2011: Added a Williams 679A "A.L.A.M." S-Shaped Wrench.

- 04/07/2011: Added a Williams 729 Open-End Wrench.

- 04/06/2011: Added a Williams Early 1096 Tappet Wrench.

- 03/07/2011: Added a

Williams 8729 Special Offset Box Wrench.

- 03/01/2011: Added a

Williams 595 "Skinner Chuck" Toolpost Wrench.

- 02/27/2011: Added a Williams 8731A Offset Box Wrench.

- 02/25/2011: Added a

Williams 8032A "Duohex-Box" Offset Box Wrench.

- 02/24/2011: Added a Williams 4731B Box-End Wrench.

- 02/19/2011: Added a Williams Early 1162 Combination Wrench

and a Williams 1324 Open Flare-Nut Wrench.

- 02/07/2011: Added a Williams 662D S-Shaped Wrench.

- 02/05/2011: Added a Williams No. 5 Single-Open Engineer's Wrench.

- 02/04/2011: Added a Williams Early 29 Open-End Wrench.

- 01/30/2011: Added a

Williams 1163 Combination Wrench.

- 01/28/2011: Added a

Williams A1721 Ribbed-Style Open-End Wrench.

- 01/25/2011: Added a Williams Early 1092-B Tappet Wrench.

- 01/21/2011: Added a Williams 1733 Open-End Wrench.

- 01/12/2011: Added a Williams 6 Inch Adjustable Wrench.

- 01/01/2011: Added a Williams 1026 Open-End Wrench.

- 12/24/2010: Added a Williams 763A Textile Wrench.

- 12/04/2010: Added a Williams No. 2 Single-Open Wrench.

- 12/03/2010: Added a Williams 1803A Single-Box Wrench.

- 11/10/2010: Added a Williams [763A] 25/32x7/8 Textile Wrench.

- 11/09/2010: Added a Williams No. 34 Open-End Wrench.

- 11/01/2010: Added a Williams 6725 Short Box Wrench.

- 10/31/2010: Added a Williams 2723 Obstruction Wrench.

- 10/23/2010: Added a

Williams 287T 5/16-Hex Drive Sliding Tee Handle

and a Williams 287S 5/16-Hex Drive Rotating-Grip Extension.

- 10/21/2010: Added a

Williams No. 287A Midget Electrical Set.

- 10/07/2010: Added a

Williams 1472 Superrench Adjustable Spanner.

- 09/29/2010: Added a Williams 4038B Box-End Wrench.

- 09/28/2010: Added a Williams 4739 Box-End Wrench.

- 09/12/2010: Added a Williams B-30 3/8-Drive Offset Handle.

- 09/06/2010: Added a Williams 1731A Open-End Wrench.

- 09/05/2010: Added a Williams 1166 3/4 Combination Wrench.

- 08/27/2010: Added a Williams 1163 9/16 Combination Wrench.

- 08/22/2010: Added a Williams 1807 Single-Box Wrench.

- 08/10/2010: Added a Williams 1723 Open-End Wrench.

- 08/03/2010: Added a Williams Early 90 Tappet Wrench.

- 07/31/2010: Added a Williams 625 Check-Nut Wrench.

- 07/30/2010: Added a Williams Early 94 Tappet Wrench.

- 07/26/2010: Added a Williams 1731A Open-End Wrench.

- 07/22/2010: Added a Williams Early 25 Open-End Wrench.

- 07/21/2010: Added a

Williams A1027B Ribbed-Style Open-End Wrench.

- 07/20/2010: Added a Williams 8132 Single-Offset Box Wrench

and a Williams "A" 1/2x19/32 Open-End Wrench.

- 07/13/2010: Added a Williams 1134 "Ratcho" Open-End Wrench.

- 07/12/2010: Added a Williams AP-12 Adjustable Wrench.

- 07/08/2010: Added a Williams 1033-A Open-End Wrench.

- 07/07/2010: Added a

Williams Early 8140 Single-Offset Box Wrench.

- 07/04/2010: Added a Williams Early 1034 Open-End Wrench.

- 06/29/2010: Added a Williams 1096 Tappet Wrench.

- 06/24/2010: Added a Williams S-43 1/2-Drive Flex Handle.

- 06/14/2010: Added a Williams 4721 Box-End Wrench.

- 06/07/2010: Added a Williams NM-51 1/4-Drive Ratchet.

- 05/25/2010: Added a

Williams A1037 Ribbed-Style Open-End Wrench.

- 05/15/2010: Added a Williams 1165 Combination Wrench.

- 05/05/2010: Added a Williams SV-244 Specialty Box Wrench.

- 05/02/2010: Added a Williams 4723 Box Wrench.

- 04/29/2010: Added a Williams 92 Tappet Wrench.

- 04/24/2010: Added a Williams 92 Tappet Wrench.

- 04/22/2010: Added a Williams C90 Tappet Wrench.

- 04/21/2010: Added a Williams Early 96 Tappet Wrench.

- 04/17/2010: Added a Williams 1090 Tappet Wrench.

- 04/13/2010: Added a Williams C92 Tappet Wrench.

- 09/15/2009: Added a Williams S-102P 2 Inch Extension.

- 09/02/2009: Added a

Williams 1029 Ribbed-Style Open-End Wrench.

- 08/28/2009: Added a Williams 628 Check-Nut Wrench.

- 08/27/2009: Added a

Williams 8 Inch "Superjustable" Wrench.

- 08/14/2009: Added a Williams 726 Open-End Wrench.

- 08/13/2009: Added a Williams 2025 Obstruction Wrench.

- 08/09/2009: Added Williams PL-16 Thin-Nose Combination Pliers.

- 08/02/2009: Added a Williams S-231 Double Socket Wrench.

- 07/25/2009: Added a Williams 1164 Combination Wrench.

- 07/22/2009: Added a

Williams X-1248 1 Inch Hex Drive Socket.

- 07/21/2009: Added a Williams A1039C Open-End Wrench

and a Williams 1165 Combination Wrench.

- 07/11/2009: Added a Williams 8725 Offset Box Wrench.

- 07/10/2009: Added a

Williams 634 Check-Nut Wrench.

- 07/05/2009: Added a

Williams 41 "Mack" Open-End Wrench.

- 07/04/2009: Added a

Williams B-50A 1/4-Drive Refrigeration Ratchet.

- 07/03/2009: Added a Williams 1166 Combination Wrench.

- 07/02/2009: Added a

Williams 1725 Ribbed-Style Open-End Wrench.

- 06/25/2009: Added a Williams 7731A Box Wrench.

- 06/24/2009: Added a

Williams 1318 Combination Open-Flare Wrench.

- 06/11/2009: Added a

Williams 1990 "Special" (A183907) Brake Wrench.

- 06/09/2009: Added a Williams 1033C Open-End Wrench.

- 06/07/2009: Added a Williams 1735 Open-End Wrench.

- 06/06/2009: Added a Williams Early 1029 Open-End Wrench.

- 06/04/2009: Added a Williams 1034 Open-End Wrench

and a Williams 1731A Open-End Wrench.

- 06/03/2009: Added a Williams 2725 Obstruction Wrench.

- 05/12/2009: Added a Williams 662B S-Shaped Wrench.

- 04/24/2009: Added a Williams 1984X Double-Square Brake Wrench.

- 04/22/2009: Added a Williams 7725B Box Wrench.

- 04/07/2009: Added Williams 1516 "Steeldraulic" Brake Pliers.

- 04/02/2009: Added a

Williams 4 Inch "Superjustable" Wrench.

- 03/26/2009: Added a Williams 8735A Offset Box Wrench.

- 03/24/2009: Added a Williams 8037 Offset Box Wrench.

- 03/22/2009: Added a Williams 7033C Box Wrench.

- 03/21/2009: Added a Williams 634 Check-Nut Wrench

and a Williams 1168 Combination Wrench.

- 03/18/2009: Added a Williams 662D S-Shaped Wrench.

- 03/07/2009: Added a Williams 8 Inch Adjustable Wrench.

- 03/06/2009: Minor reorganization of box wrenches,

added a Williams B-55 3/8-Drive Ratchet Adapter.

- 02/27/2009: Added a Williams 8029B Offset Box Wrench.

- 02/26/2009: Added a Williams SP-420 Square Plug Socket,

updated discussion of adjustable wrenches.

- 02/25/2009: Added a Williams 1731 Open-End Wrench

and a Williams SP-20B Handle Bar.

- 02/24/2009: Added a

Williams No. 100 Drain Plug Socket Set

and a

Williams SP-20E 1/2-Drive Sliding Tee Head.

- 02/22/2009: Added a Williams 727 Open-End Wrench

and a box for the

Williams 10 Inch "Superjustable" Wrench.

- 02/19/2009: Added a

Williams 10 Inch "Superjustable" Wrench.

- 02/16/2009: Added a Williams 7727 Box Wrench.

- 02/15/2009: Added a Williams 1723 Open-End Wrench.

- 02/14/2009: Added a Williams 993 Early Spark Plug Wrench.

- 02/12/2009: Added a Williams 1127C "Ratcho" Wrench.

- 02/10/2009: Added a Williams 79S "Mack" S-Shaped Wrench.

- 02/06/2009: Added a Williams 8029 Offset Box Wrench.

- 02/01/2009: Updated trademark section.

- 01/24/2009: Added a

Williams 1725B Ribbed-Style Open-End Wrench.

- 01/23/2009: Added a Williams 1033C Open-end Wrench.

- 01/22/2009: Added a

Williams A1725B Ribbed-Style Open-end Wrench.

- 01/13/2009: Added a Williams 1171 Combination Wrench.

- 01/08/2009: Added a

Williams 1041 Ribbed-Style Open-End Wrench.

- 01/06/2009: Added a Williams Early No. 33 Open-End Wrench

and a Williams B-115 3/8-Drive Extension.

- 01/05/2009: Added a Williams Early No. 27 Open-End Wrench.

- 01/02/2009: Added a Williams 1733 Open-End Wrench.

- 12/25/2008: Added a Williams AP-10 Adjustable Wrench.

- 12/18/2008: Added a Williams F-50 3/8-Drive Ratchet.

- 12/17/2008: Added a Williams 2023 Obstruction Wrench.

- 12/13/2008: Added a Williams 1128 Ignition Wrench.

- 12/09/2008: Added a Williams 1132 Ignition Wrench

and a Williams 1959 Starter & Manifold Wrench.

- 12/06/2008: Added a Williams 8031 Offset Box Wrench.

- 12/04/2008: Added a Williams 1034A Open-End Wrench.

- 11/23/2008: Added a Williams 1028 Open-End Wrench.

- 11/16/2008: Added a

Williams 1029 Open-End Wrench.

- 10/27/2008: Added a Williams 6 Inch "Superjustable" Wrench.

- 10/22/2008: Added a Williams 1725B Open-End Wrench.

- 10/19/2008: Added a Williams 2033A Obstruction Wrench.

- 10/06/2008: Added a

Williams M-110 1/4-Drive Convertible Handle.

- 10/01/2008: Added a Williams 1985 Brake Wrench.

- 09/27/2008: Updated catalog resources.

- 09/15/2008: Added a Williams No. 6 Open-End Wrench.

- 09/13/2008: Added a Williams 4 Inch Adjustable Wrench.

- 09/11/2008: Added a Williams 7723 Box Wrench.

- 09/09/2008: Added a Williams 1983 Brake Wrench.

- 09/08/2008: Added a Williams 1092F Tappet Wrench.

- 09/07/2008: Added a Williams 2029 Obstruction Wrench.

- 09/05/2008: Added a Williams 1033C Open-End Wrench.

- 09/04/2008: Added a Williams 1033 Open-End Wrench.

- 09/02/2008: Added a Williams 1031 Open-End Wrench.

- 09/01/2008: Added a

Williams 1029 Open-End Wrench.

- 08/29/2008: Added a Williams 1163 Combination Wrench.

- 08/28/2008: Added a

Williams 8960 Double-ended Water-Pump Wrench.

- 08/27/2008: Added a Williams 1731-A Open-End Wrench.

- 08/25/2008: Added a Williams 1106 Ignition Wrench.

- 08/23/2008: Added a Williams 1981 Socket Wrench.

- 08/21/2008: Added a Williams 993 Spark Plug Wrench.

- 08/18/2008: Added a

Williams SU-1222 1/2-Drive Universal Socket.

- 08/14/2008: Added a Williams 1113 Ignition Wrench.

- 08/13/2008: Added a Williams M-52 Ratchet.

- 08/11/2008: Added a Williams 1092-F Tappet Wrench

and a Williams 1161 Combination Wrench.

- 08/10/2008: Added a

Williams XOEE-1220 Short Combination Wrench.

- 08/09/2008: Added a

Williams Early S-40 1/2-Drive Breaker Bar.

- 08/08/2008: Added a Williams 8034A Offset Box Wrench.

- 08/07/2008: Added a Williams 8037A Offset Box Wrench.

- 08/05/2008: Added a Williams 1027 Open-End Wrench.

- 08/04/2008: Added a Williams XOEE-1218 Short Combination Wrench

and a Williams A731A Open-End Wrench.

- 08/03/2008: Added a Williams 1725B Open-End Wrench

and a Williams 4725B Box Wrench.

- 08/02/2008: Added a Williams 3033A Open-End Wrench.

- 07/31/2008: Added a Williams 1023 Open-End Wrench

and a Williams 1029 Open-End Wrench.

- 07/30/2008: Added a Williams 1166A Combination Wrench.

- 07/29/2008: Added a Williams 3731 Open-End Wrench.

- 07/28/2008: Added a Williams 1025 Open-End Wrench.

- 07/25/2008: Added a Williams 725 Open-End Wrench.

- 07/24/2008: Split into six pages,

added a Williams 1720 Open-End Wrench

and a Williams 1312 Combination Open-Flare Wrench.

- 07/23/2008: Added a Williams 1159 Combination Wrench.

- 07/22/2008: Added a Williams 1092-F Tappet Wrench,

a Williams 8140 Single-Offset Box Wrench,

and a Williams S-20C 1/2-Drive Offset Sliding Tee Handle.

- 07/21/2008: Added a Williams 1029 Open-End Wrench

and a Williams A1033C Open-End Wrench.

- 07/19/2008: Added a Williams 1027B Open-End Wrench.

- 07/18/2008: Updated discussion of alloy specifications.

- 07/17/2008: Added a Williams 1316 Open-Flare Wrench.

- 07/16/2008: Added a Williams 1023 Open-End Wrench

and a Williams 1027 Open-End Wrench.

- 07/15/2008: Added a Williams S-1225 1/2-Drive Socket.

- 07/14/2008: Added a Williams 1125 Special "Ratcho" Wrench.

- 07/12/2008: Added a Williams B-40 3/8-Drive Flex Handle.

- 07/10/2008: Added a Williams 1107 Ignition Wrench.

- 07/07/2008: Added a Williams [No. 726] Open-End Wrench

and a Williams 1115 Ignition Wrench.

- 07/06/2008: Added a Williams 1124 Ignition Wrench

and a Williams 5/8x25/32 Open-End Wrench.

- 07/04/2008: Added a Williams 1108A Ignition Wrench.

- 07/03/2008: Added a Williams 1114 Ignition Wrench.

- 06/28/2008: Added a Williams 8039 Offset Box Wrench

and a Williams H-51 3/4-Drive Ratchet.

- 06/27/2008: Added a Williams 2728 Obstruction Wrench.

- 06/25/2008: Added a Williams S-10P 1/2-Drive Brace.

- 06/24/2008: Added a Williams Early 731B Open-End Wrench.

- 06/22/2008: Added a Williams 725 Open-End Wrench,

a Williams 664A S-Shaped Wrench,

a Williams 2021 Obstruction Wrench,

and a Williams 2028 Obstruction Wrench.

- 06/21/2008: Added a Williams 2729 Obstruction Wrench

and a Williams 2028S Obstruction Wrench.

- 06/20/2008: Added a Williams 2032 Obstruction Wrench

and a Williams 6727 Short Box Wrench.

- 06/18/2008: Added a Williams 3/4x7/8 Open-End Wrench.

- 06/15/2008: Added a Williams 762 Special Textile Wrench

and a Williams 1120 Ignition Wrench.

- 06/11/2008: Added a Williams 683A S-Shaped Wrench.

- 06/09/2008: Added a Williams Early 29 Open-End Wrench.

- 05/27/2008: Added a Williams 1025 Open-End Wrench.

- 05/21/2008: Added a Williams S-40A 1/2-Drive Breaker Bar

and a Williams M-110 9/32-Drive Handle Extension.

- 05/18/2008: Added a Williams 9/16x11/16 Open-End Wrench.

- 05/09/2008: Added a Williams F-50 3/8-Drive Ratchet.

- 05/03/2008: Added a Williams B-108 3/8-Drive Extension.

- 05/01/2008: Added a Williams 1515 Snap-Ring Pliers.

- 04/18/2008: Added a

Williams 9727 "Duohex-Box" Offset Box Wrench.

- 04/17/2008: Added a Williams C-98 Wood Chisel.

- 04/14/2008: Added a

Williams "Ratcho" Ratcheting Open-End Wrench.

- 04/11/2008: Added a

Williams 723A "Pierce-Arrow" Open-End Wrench.

- 04/10/2008: Added a Williams 737 Open-End Wrench.

- 04/04/2008: Added a Williams 704 Single-Open Wrench.

- 04/03/2008: Added a Williams S-1236 1/2-Drive Socket.

- 04/01/2008: Added a Williams 1122 Ignition Wrench.

- 03/27/2008: Added a Williams 1090 Tappet Wrench.

- 03/22/2008: Added a Williams 8725B Offset Box Wrench

and a Williams BA-5 3/8-Drive Hex Driver.

- 03/21/2008: Added a Williams S-110P 1/2-Drive Extension.

- 03/14/2008: Added a Williams 1727 Open-End Wrench.

- 03/09/2008: Added a Williams 761 Special Textile Wrench.

- 03/07/2008: Added a

Williams B-42 3/8-Drive Flex-Head Breaker Bar.

- 03/03/2008: Added a Williams 1161 7/16 Combination Wrench.

- 02/27/2008: Added a

Williams NX-20B/C 1 Inch Drive Sliding Tee Bar.

- 02/26/2008: Added a Williams S-15A 1/2-Drive Speeder

and a Williams NX-51 1 Inch Drive Ratchet.

- 02/25/2008: Added a

Williams 1031 Ribbed-Style Open-End Wrench.

- 02/23/2008: Added a

Williams A1031B Ribbed-Style Open-End Wrench.

- 02/22/2008: Added a

Williams 1034A Ribbed-Style Open-End Wrench.

- 02/05/2008: Added Williams MP-1 and MP-2 1/4-Drive Screwdrivers

and a Williams NM-2 1/4-Drive Socket Set.

- 02/04/2008: Added a Williams NM-7 1/4-Drive Socket Set.

- 02/03/2008: Added a Williams 1116 Ignition Wrench.

- 02/02/2008: Added a Williams 1114 Ignition Wrench.

- 01/30/2008: Added a Williams 1291P Midget Electrical Set.

- 01/29/2008: Added a Williams B-20A 3/8-Drive Breaker Bar.

- 01/27/2008: Added a

Williams 1/2-Hex Drive S-50 Ratchet.

- 01/22/2008: Added a Williams 1132 Ignition Wrench

and a Williams A27C Open-End Wrench.

- 01/17/2008: Added a Williams S-41 1/2-Drive Breaker Bar

and a Williams M-115 1/4-Drive Extension.

- 01/16/2008: Added a Williams 807 Single-Box Wrench.

- 01/14/2008: Added a Williams 1090a Tappet Wrench.

- 01/12/2008: Minor reorganization, split into five pages.

- 01/10/2008: Added a Williams 8727 Offset Box-End Wrench.

- 01/09/2008: Added a Williams H-1260 3/4-Drive Socket.

- 01/07/2008: Updated catalog resources.

- 01/01/2008: Added a Williams B-52 3/8-Drive Ratchet.

- 12/31/2007: Added a Williams 1998B Brake Spoon.

- 12/30/2007: Added a Williams WSM-1A 1/4-Drive Socket Set

and a Williams 1328 Open Flare-Nut Wrench.

- 12/19/2007: Added a Williams M-106 1/4-Drive Handle.

- 12/17/2007: Added a Williams 7733 Box-End Wrench

and a Williams H-41A 3/4-Drive Breaker Bar.

- 12/16/2007: Added a Williams S-15P 1/2-Drive Speeder

and a Williams S-5 1/2-Drive Socket Set.

- 12/15/2007: Added a Williams 1033C Open-End Wrench.

- 12/13/2007: Added a Williams 4040B Box-End Wrench.

- 12/12/2007: Added a Williams 1176 Combination Wrench.

- 12/11/2007: Added a Williams S-15 1/2-Drive Speeder.

- 12/09/2007: Added a Williams "A" Open-End Wrench.

- 12/08/2007: Added a Williams No. 30 Open-End Wrench.

- 12/07/2007: Added

Williams ST-12xx Double-Groove Sockets.

- 12/06/2007: Added Williams ST-12xx Transitional Sockets

and a Williams SC-8 1/2-Drive Adjustable Crowfoot.

- 12/05/2007: Added a Williams 529 Toolpost Wrench

and a Williams S-1 1/2-Drive Socket Set.

- 12/04/2007: Added a Williams 1997 Offset Screwdriver.

- 11/24/2007: Added a Williams 729 "White" Open-End Wrench

and a Williams 483 Adjustable Face Spanner.

- 11/17/2007: Added a Williams S-60C 1/2-Drive Stud Extractor.

- 11/15/2007: Added a Williams H-1244 3/4-Drive Socket.

- 11/12/2007: Added a Williams 1021S Brake Wrench.

- 11/10/2007: Added a Williams "A" Open-End Wrench.

- 11/07/2007: Added a Craftsman 44604 Adjustable Wrench.

- 11/06/2007: Added a Williams NX-1240 1 Inch Drive Socket.

- 11/05/2007: Added a Williams NX-1264 1 Inch Drive Socket.

- 11/04/2007: Added a Williams No. 81 1 Inch Drive Socket Set

and a Williams 18021 Offset Box Wrench.

- 11/03/2007: Added a Williams 635E Check-Nut Wrench

and a Williams 1723 Open-End Wrench.

- 11/02/2007: Added a Williams NX-20B Breaker Bar.

- 11/01/2007: Added a Williams 4739 Box-End Wrench.

- 10/18/2007: Added a Craftsman 8 Inch Adjustable Wrench.

- 10/13/2007: Added a Williams 1152 Box-End Ignition Wrench

and a Williams S-51 1/2-Drive Ratchet.

- 10/07/2007: Added a Williams 969A Socket Wrench

and a Williams "A" Open-End Wrench.

- 10/06/2007: Added a Williams 1027 Open-End Wrench.

- 10/05/2007: Minor reorganization of sections,

added a Williams 7721 Box Wrench.

- 10/04/2007: Added a

Williams No. 1999 Multi-Socket Wrench.

- 09/25/2007: Added a Williams 864F "S" Wrench

and a Williams 1090D Tappet Wrench.

- 09/22/2007: Added a Williams 529 Toolpost Wrench.

- 09/21/2007: Added a Williams Early 731 Open-End Wrench.

- 09/07/2007: Added a Williams 9725B Offset Box Wrench.

- 09/02/2007: Added a Williams 663E S-Shaped Wrench.

- 08/25/2007: Added a Williams No. 2 Bull Dog Wrench.

- 08/20/2007: Added a Williams Early 762C Textile Wrench.

- 08/18/2007: Added a Williams 1732 Open-End Wrench.

- 08/12/2007: Added a Williams 8946 Water Pump Wrench.

- 08/11/2007: Added a Williams 1096H Tappet Wrench.

- 08/10/2007: Added a Williams 7025 Box-End Wrench.

- 08/04/2007: Added a Williams 8962D Water Pump Wrench.

- 07/26/2007: Added a Williams 1096H Special Tappet Wrench.

- 07/25/2007: Added a Williams 8946 Water Pump Wrench.

- 07/17/2007: Added a Williams 8727A Offset Box Wrench.

- 07/10/2007: Added a Williams 1132 Ignition Wrench.

- 07/09/2007: Added a Williams 1721 Open-End Wrench.

- 07/01/2007: Added a Williams A1723A Open-End Wrench.

- 06/29/2007: Added a Williams NX-115 1 Inch Drive Extension.

- 06/21/2007: Added a Williams 8045 Offset Box-End Wrench

and Williams ST-12xx 1/2-Drive Sockets.

- 06/18/2007: Added Williams H-12xx 3/4-Drive Sockets.

- 06/17/2007: Added a Williams 8033C Offset Box Wrench.

- 06/16/2007: Added a Williams X-41 1 Inch Drive Breaker Bar.

- 06/15/2007: Added a Williams 8962 Water Pump Wrench

and a Williams H-20A 3/4-Drive Breaker Bar.

- 06/14/2007: Added a Williams No. 35 Open-End Wrench.

- 06/08/2007: Added a Williams Early 761C Textile Wrench.

- 06/07/2007: Added a Williams H-1808 Single Box Box Wrench.

- 06/06/2007: Added a Williams 8733 Offset Box Wrench

and a Williams 8808 Slugging Wrench.

- 06/05/2007: Added a Williams H-115 3/4-Drive Extension.

- 06/04/2007: Added a Williams 8940 Waterpump Wrench

and a Williams 1334 Combination-Flare Wrench.

- 06/02/2007: Added a Williams 8948 Waterpump Wrench.

- 05/30/2007: Added a Williams No. 3 Open-End Wrench.

- 05/28/2007: Added a Williams H-150 3/4-Drive Ratchet Plug

and a Williams H-140 3/4-Drive Universal.

- 05/26/2007: Added a Volume VB-15 3/8-Drive Speeder.

- 05/25/2007: Added a Williams H-50 3/4-Drive Ratchet.

- 05/24/2007: Added a

Williams-Husky No. 287 Wrench Set Illustration.

- 05/22/2007: Added a

Williams H-41 3/4-Drive Breaker Bar.

- 05/16/2007: Updated patent table.

- 05/11/2007: Added a Williams H-1270 3/4-Drive Socket.

- 05/10/2007: Added a Williams 2033A Obstruction Wrench.

- 05/08/2007: Added a Williams B-15 3/8-Drive Speeder and a

Williams Early H-110 3/4-Drive Extension.

- 05/06/2007: Added a Williams S-10 1/2-Drive Brace.

- 05/04/2007: Added a Williams X-51 1 Inch Drive Ratchet.

- 05/01/2007: Added a Vulcan No. 30 Bijaw Chain Pipe Wrench.

- 04/22/2007: Added Volume VB-12xx 3/8-Drive Sockets.

- 04/20/2007: Added a Williams 4731A Box-End Wrench.

- 04/15/2007: Added a Williams 2027 Obstruction Wrench

and a Volume VB-51 3/8-Drive Ratchet.

- 04/13/2007: Added a Williams M-310 9/32-Drive Socket Set

and a Williams M-42 9/32-Drive Breaker Bar.

- 04/10/2007: Split into four pages, added a

Williams NX-110 1 Inch Drive Extension.

- 04/02/2007: Added a Williams 1023 Open-End Wrench

and a Williams 1729 Open-End Wrench.

- 03/10/2007: Added a Williams 556 Toolpost Wrench.

- 03/09/2007: Added a Williams 1998A Brake Spoon.

- 03/04/2007: Added a

Williams Early 10 Inch Superjustable Wrench.

- 03/03/2007: Added a Williams Early 1090 Tappet Wrench.

- 03/01/2007: Added a Williams 8 Inch Adjustable Wrench.

- 02/23/2007: Added Williams No. 76 Needlenose Pliers.

- 02/20/2007: Updated patent table.

- 02/18/2007: Added a Williams 1735 Open-End Wrench

and a Williams 1037 Open-End Wrench.

- 02/17/2007: Added a Williams No. 0 Chain Wrench

and a Williams 4731B Box-End Wrench.

- 02/14/2007: Added a Williams M-51 1/4-Drive Ratchet.

- 02/08/2007: Added a Williams 1170 Combination Wrench,

a Williams 472 Adjustable Spanner,

and a Volume VS-1220 1/2-Drive Socket.

- 01/29/2007: Added Williams 1520 Waterpump Pliers.

- 01/28/2007: Added a Williams Vulcan Auto Tool

and a Williams S-52 1/2-Drive Ratchet.

- 01/26/2007: Added an early

Williams Early No. 1999 Multisocket Wrench.

- 01/25/2007: Added a Craftsman 8-In-1 Socket Wrench.

- 01/23/2007: Added a Williams S-20A T-Slider Breaker Bar.

- 01/22/2007: Added a Williams 1999 Multisocket Wrench.

- 01/21/2007: Added a Williams 1034(?) Tappet Wrench.

- 01/11/2007: Added a Williams 18731A Box-End Wrench.

- 01/05/2007: Added a Williams 1726 Open-End Wrench.

- 12/31/2006: Added a Williams 662F S-Shaped Wrench

and a Williams 1727 Open-End Wrench.

- 12/21/2006: Added a Williams 3721 Open-End Wrench

and a Williams 1158 Combination Wrench.

- 12/20/2006: Added a Williams 1077-S Open-End "S" Wrench

and a Williams 1160 Combination Wrench.

- 12/19/2006: Split into three pages,

added a Williams 9723 Short Offset Box Wrench

and a Williams APL-6 Locking Adjustable Wrench.

- 12/14/2006: Added a No. 19725 Box-End Wrench

and a Williams B-52 Ratchet.

- 12/12/2006: Added a Williams 624 Check-Nut Wrench.

- 12/11/2006: Added a Williams 2027C Obstruction Wrench.

- 12/10/2006: Added a Williams 255A Socket Wrench.

- 12/09/2006: Added a Williams 1161 Combination Wrench.

- 12/06/2006: Added a Williams S-51 1/2-Drive Ratchet

and a Williams BS-71 1/2-Drive Ratchet.

- 12/03/2006: Added a Williams AP-4 Adjustable Wrench

and a Williams B-51 Ratchet.

- 12/02/2006: Added a Williams AP-8 Adjustable Wrench.

- 12/01/2006: Added a Williams 1032B Open-End Wrench.

- 11/29/2006: Added a Williams AB-8 Adjustable Wrench

and a Williams MR-51 Refrigeration Ratchet.

- 11/26/2006: Added a Williams S-30 Breaker Bar.

- 11/21/2006: Added the clever

Williams NM-110 Convertible Drive Handle.

- 11/19/2006: Added a Williams 1128 Ignition Wrench.

- 11/12/2006: Added a Williams 8936 Waterpump Wrench.

- 11/06/2006: Added patent table and wrench face markings.

- 10/30/2006: Added a 7029 Duohex-Box Wrench.

- 10/29/2006: Added a 7731B Box-End Wrench.

- 10/28/2006: Added a A723 Open-End Wrench.

- 10/23/2006: Added a 8966 Double-Ended Water Pump Superrench.

- 10/19/2006: Added a 1167A Combination Wrench.

- 10/16/2006: Renumbered figures.

- 09/30/2006: Added a 1085 Open-End "S" Wrench.

- 09/28/2006: Added a 3033A Open-End Wrench.

- 09/25/2006: Added a Early 632 Check-Nut Wrench

and a 7039B Box-End Wrench.

- 09/22/2006: Added S-12xx 12-Point Sockets.

- 09/21/2006: Added an 8731A Offset Box Wrench

and an 8029 Offset Box Wrench.

- 09/20/2006: Added an 8029B Offset Box Wrench

and an 1164 Combination Wrench.

- 09/19/2006: Split article into two pages,

added an 8037 Duohex-Box Offset Wrench.

- 09/18/2006: Added a 2021 Obstruction Wrench.

- 09/17/2006: Added a 2731A Obstruction Wrench.

- 09/16/2006: Added a 1167 Combination Wrench.

- 09/15/2006: Added a 1096 Flat-Shank Tappet Wrench.

- 09/14/2006: Added an 8729 Paneled Offset Box Wrench

and a 7727A Box Wrench.

- 09/10/2006: Added an 8729 Duohex-Box Offset Box Wrench.

- 09/09/2006: Added an 8128 Single-Offset Box Wrench

and an 8140 Single-Offset Box Wrench.

- 09/03/2006: Added a group of early S-4xx Square Sockets

and a S-40 1/2-Drive Breaker Bar.

- 09/01/2006: Added a 525 Toolpost Wrench.

- 08/31/2006: Added a 1729 Ribbed Open-End Wrench

and a 9723 Offset Box-End Wrench.

- 08/30/2006: Added a Williams 1029 Open-End Wrench

and a 7725B Raised-Panel Box-End Wrench.

- 08/29/2006: Added a A90 Tappet Wrench,

a 633 Mack Check-Nut Wrench,

and a B-40 3/8-Drive Breaker Bar.

- 08/26/2006: Added a 2028S Obstruction Wrench.

- 08/25/2006: New table of catalogs,

added a S-1240 1/2-Drive Socket.

- 08/24/2006: Added a S-50 1/2-Drive Ratchet.

- 08/23/2006: Added a S110 1/2-Drive Rotating-Grip Extension.

- 08/22/2006: Added a No. 21R 1/2-Drive Socket Set.

- 08/18/2006: Added a S115 Rotating-Grip Extension.

- 08/17/2006: Added a 1731 Superrench Open-End Wrench.

- 08/11/2006: Added a S-1234 12-Point Socket

and a S-824 8-Point Socket.

- 08/01/2006: Added a 8729A Duohex-Box Offset Wrench.

- 07/31/2006: Added a 7729 Box-End Wrench.

- 07/21/2006: Added a 6723 Box-End Wrench

and a 7727A Box-End Wrench.

- 07/20/2006: Added a 1164 Combination Wrench.

- 07/19/2006: Added a 1727 Ribbed-Style Open-End Wrench.

- 07/14/2006: Added a 31 Open-End Wrench.

- 07/12/2006: Added a 8938 Water Pump Superrench

and a S-50 Ratchet.

- 06/17/2006: Created page, no content yet.

Introduction

J.H. Williams & Company was an early merchant drop-forger and grew to become one of the largest

and most important tool makers.

The company is generally credited with developing the industry-standard numbering system for wrenches

widely used from the late 19th through the mid 20th centuries.

Company History

J.H. Williams & Company

was founded by James H. Williams and initially operated as Williams & Diamond in Flushing, New York.

Prior to his partnership with Diamond,

Williams had been a partner in Bliss & Williams,

a maker of machinery for stamping and shaping sheet metal.

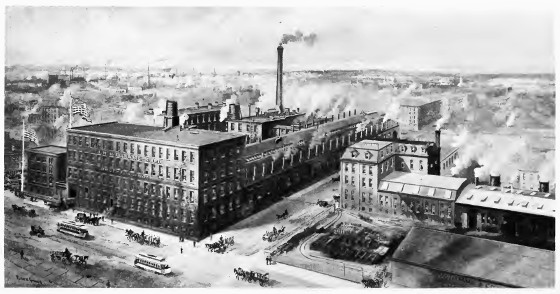

Fig. 2 illustrates a Bliss & Williams press,

as published on page 401 of the December 27, 1871 issue of American Artisan.

On February 7 of 1881

Bliss and Williams dissolved their partnership by mutual agreement,

and the partners moved on to new endeavors.

Fig. 3 shows

a notice of the dissolution of the Bliss & Williams partnership,

as published on

page 20

[External Link] of the February 19, 1881 issue of The Metal Worker.

After leaving Bliss & Williams,

J.H. Williams formed a partnership with Matthew Diamond in 1882 as Williams & Diamond

to produce drop-forgings in Flushing, New York.

In 1884 Williams & Diamond

was reorganized as J.H. Williams & Company,

and shortly afterwards the company moved to Brooklyn.

Fig. 4 shows

a notice for J.H. Williams & Company,

as published on page 152 of the May 1, 1884 issue of The Hub.

The text notes that the company formerly operating as Williams & Diamond

in Flushing would be moving on June 1st (1884) to Brooklyn,

at the corner of Richards and Bowne Streets.

(In later catalogs Williams generally used the June 1, 1884 move to Brooklyn as its founding date,

although the operating partnership began two years prior to this.)

Additional corroboration of the move to Brooklyn can be found in an obituary for James H. Williams on

page 57

[External Link] of the December 8, 1904 issue of The Iron Age.

The article notes that the company moved to Brooklyn on July 1, 1884 and was renamed to J.H Williams & Company.

(This differs slightly from the June 1, 1884 date cited previously.)

The company was later incorporated on July 1, 1895 with Williams as president.

Chain Pipe Wrenches

Chain pipe wrenches based on various patents by W.H. Brock were an important early product

for J.H. Williams.

Fig. 5 shows

an ad for a J.H. Williams "Brock's Patent" chain pipe wrench,

as published on page iii of the March 20, 1886 issue of The Mechanical Engineer.

Standardized Wrenches

In the early years of the drop-forging industry,

wrenches were typically made as custom orders,

with each customer (typically a maker of machinery) specifying what sizes and combinations of openings they wanted.

Since there was already a degree of standardization in bolt and nut sizes,

Williams realized that making standarized wrenches would be much more efficient

than handling lots of orders for custom wrenches.

By as early as 1883 Williams (as Williams & Diamond at that time) was already making

standard open-end wrenches,

based on a report on

page 6

of the September 8, 1883 issue of American Machinist.

Within a few years standard open-end wrenches were available in both single and double-ended styles,

and in a wide range of sizes.

Fig. 6 shows

an ad for Williams drop-forged engineers' wrenches,

as published on page 187 of the February, 1888 edition of the Locomotive Engineers' Monthly Journal.

The text notes that the wrenches were available in 42 sizes to fit U.S. Standard nuts and bolts,

and mentions the 15 degree head offset to allow turning hexagon nuts with limited clearance.

Williams claimed to have originated the 15 degree offset design for open-ended wrenches,

but the design was soon copied by other manufacturers.

By 1901 Williams

had expanded their selection of U.S. Standard wrenches to include 25 sizes

of single-ended engineers' wrenches and 48 sizes of double-ended wrenches.

Fig. 7 shows

a listing of U.S. Standard single-ended engineers' wrenches,

as published on page 11 of the 1901 Williams 10th edition catalog.

The 25 sizes cover a range of openings from 5/16 up to 5-3/8(!) inches.

Double-ended wrenches

for U.S. Standard nuts were listed in 48 sizes from model 21 (5/16x13/32) up to model 64 (4-5/8x5-3/8).

The 1901 catalog also offered wrenches for the Hexagon Cap-Screw standard

in a 7xx series.

Fig. 8 shows

a listing of Hexagon Cap-Screw wrenches in single and double-ended styles,

as published on page 15 of the 1901 Williams 10th edition catalog.

The tables show 11 sizes of single-ended wrenches from model 700 (3/8) to 708 (1-1/4),

and 21 sizes of double-ended wrenches from model 723 (3/8x7/16) to 737 (1-1/8x1-1/4).

The model numbers assigned by Williams formed the basis for the Industry Standard Numbering (ISN) system for wrenches,

and these model numbers were adopted by most other wrench manufacturers.

More information on the ISN system can be found on our page on

Industry-Standard Numbers for Open-End Wrenches.

The Big Nine

By mid 1918 the American involvement in World War I was increasing rapidly,

and the War Industries Board was seeking changes in certain industries,

in order to conserve manpower and materials in the event of a long conflict.

In late summer J.H. Williams was one of the "Big Nine" tool companies to sign an agreement for

the changes requested by the Board.

The agreement can be seen as the

1918 War Conservation Changes

in our article on Herbrand,

another of the "Big Nine" companies.

The war ended shortly after that,

so the changes had only a short-term effect,

but the statement is significant in showing the structure of the tool industry at that time.

The Superrench Era

In 1925 Williams introduced its "Superrench" line of chrome-molybdenum alloy steel wrenches.

Prior to this time Williams had experimented with tappet wrenches made of alloy steel,

but had watched from the sidelines as

Bonney Forge and Tool rolled out a full line of very popular

"CV" chrome-vanadium wrenches beginning in late 1922.

The "Superrench" line initially offered four patterns:

engineers' wrenches with 15 degree offset heads,

general purpose "S" wrenches, single-ended construction wrenches with a 15 degree offset,

and structural wrenches with a straight head and offset handle.

In its application for the "Superrench" trademark,

Williams claimed a first use date of October 10, 1925.

Fig. 9 shows

an early notice for the Williams "Superrench" line,

as published on page 1890 of the November 19, 1925 issue The Iron Age.

The text notes that the wrenches were drop-forged from chrome-molybdenum steel,

and that this allowed the tools to be designed with thinner sections and lighter weight.

Fig. 10 shows

an early ad for the Williams "Superrench",

as published on page 85 of the January, 1926 issue of American Exporter.

The text notes the use of chrome-molybdenum steel and a nickel-plated finish;

by 1927 the finish had been changed to chrome plating over nickel.

By June of 1926 tappet wrenches had been added to the "Superrench" line,

and "Superrench" angle-head obstruction wrenches were available by 1927.

Brake Service Wrenches

Automobile brake service required specialized tools for some brands,

including wrenches with unusual openings or configurations.

Fig. 11 shows

a full-page ad for the Williams "Superrench" No. 1950 brake wrench set,

as published on page 31 of the January, 1929 issue of Motor Record.

This advertisement shows that by the late 1920s Williams had begun adding automotive specialty tools

to the "Superrench" line.

Collaboration with Husky Wrench

By the late 1920s the Williams "Superrench" line had become very successful,

but the company still lagged the tool industry in one aspect:

Williams did not offer interchangeable sockets and drive tools.

Williams sought to address this gap in their product line by partnering with the Husky Wrench Company of Milwaukee,

to offer "combination" sets consisting of Williams "Superrench" wrenches and Husky socket tools.

Such sets were popular at the time,

and since Williams didn't make socket tools and Husky didn't make open-end wrenches,

the arrangement was potentially beneficial for both companies.

Fig. 12A shows

a notice of the collaborative arrangement between J.H. Williams and Husky Wrench,

as published on page 66 of the May, 1928 edition of Power Wagon.

A slightly later notice provides

further clarity on the agreement between Williams and Husky.

The scan in Fig. 12B shows

a notice regarding the reciprocal sales agreement between Williams and Husky,

as published on

page 65

[External Link] of the July 14, 1928 issue of Automotive Industries.

The text notes that the reciprocal agreement was only for sales purposes,

and that the agreement covered only part of the product lines of the companies.

One result of the Husky agreement was that Williams developed a new line of "Midget Superrench" ignition wrenches,

which were then included with Husky's 5/16-hex drive miniature sockets to create a "Combination Electrical Set".

Williams apparently kept good records of their development work,

as the later filing of the "Midget" Trademark #277,309

provides a precise first use date of May 17, 1928 for the "Midget Superrench" ignition wrenches.

An example of these sets can be seen as the

Williams No. 287 Combination Electrical Set.

The collaboration with Husky Wrench was short-lived,

but served to convince Williams of the importance of the socket market.

By mid 1930 Williams was making its own sockets and drive tools,

but continued to use the 5/16-hex drive size for the miniature sockets.

The Volume Line

More than a decade ago we rediscovered an almost-forgotten secondary brand for Williams called

"Volume" in a distributor catalog.

Subsequently we were able to acquire a modest selection of "Volume" tools,

including wrenches, drive tools, and even a reasonably complete socket set.

With the recent (February 2022) discovery of the "VOLUME"

Trademark #256,651,

filed in January of 1929,

we now have a clearer view of Williams' intentions in establishing in the brand.

The scan in Fig. 12C shows

an ad for Williams "Volume" wrenches,

as published on

page 104

[External Link] of the July, 1929 issue of Popular Science Monthly.

The illustration at the bottom shows wrench set "VA",

a set of six chrome-molybdenum open-end wrenches with openings ranging from 3/8 to 1 inch.

The wrenches were secured in a metal clip described by patent

1,889,203,

filed by W.C. Kress on June 14, 1929 and issued in 1932.

The metal clip had a novel fanfold design that provided a separate pocket for each wrench.

Readers familiar with the Vlchek Tool Company will recognize similarities

between the two company's wrench sets.

Vlchek had long provided popularly priced carbon-steel wrenches,

but in the late 1920s began offering chrome-molybdenum alloy steel wrenches in

"FITZ ALL" sets secured by a metal clip.

A Full Service Vendor

By the mid 1930s Williams had become a full-service vendor for automotive and industrial service tools.

Fig. 12D shows

a full-page ad for Williams wrenches and socket tools,

as published on page 19 of the December, 1940 issue of Motor.

The illustration provides an overview of Williams' extensive selection of service tools,

including open-end, box-end, combination, and adjustable wrenches,

as well as socket tools in drive sizes 1/4, 3/8, 1/2, and 3/4.

J.H. Williams & Co.: Issued and Licensed Patents

| Patent No. | Inventor | Filed | Issued | Notes and Examples |

| 247,987 |

W.H. Brock | 08/05/1881 | 10/04/1881 |

Chain Pipe Wrench

Williams No. 0 Chain Wrench

|

| 250,641 |

W.H. Brock | 11/02/1881 | 12/13/1881 |

Chain Pipe Wrench

Williams No. 0 Chain Wrench

|

| 254,862 |

W.H. Brock | 02/09/1882 | 03/14/1882 |

Chain Pipe Wrench

Williams No. 0 Chain Wrench

|

| 298,442 |

W.H. Brock | 02/02/1884 | 05/13/1884 |

Chain Pipe Wrench

Williams No. 0 Chain Wrench

|

| 377,795 |

J.H. Williams | 05/23/1887 | 02/14/1888 |

Chain Pipe Wrench

Williams No. 0 Chain Wrench

|

| RE11,277 |

H. Hammond | 07/18/1892 | 10/18/1892 |

Adjustable Wrench |

| 542,136 |

J.C. Booth | 05/02/1894 | 07/02/1895 |

Chain Pipe Wrench |

| 570,213 |

G. Amborn, Jr. | 04/06/1896 | 10/27/1896 |

Chain Pipe Wrench |

| 570,214 |

G. Amborn, Jr. | 06/01/1896 | 10/27/1896 | Chain Pipe Wrench |

| 577,653 |

W.J. Grinden & G. Amborn, Jr. | 04/01/1896 | 02/23/1897 | Chain Pipe Wrench |

| 577,654 |

W.J. Grinden & G. Amborn, Jr. | 04/01/1896 | 02/23/1897 | Chain Pipe Wrench |

| D35,385 |

G. Amborn, Jr. | 07/22/1901 | 12/03/1901 | Pipe Wrench |

| 697,977 |

G.W. Bufford | 01/27/1902 | 04/22/1902 | Pipe Wrench |

| 876,925 |

G. Amborn | 03/08/1907 | 01/21/1908 | Chain Pipe Wrench |

| 876,926 |

G. Amborn | 05/06/1907 | 01/21/1908 |

Chain Pipe Wrench ["Bijaw"]

Vulcan No. 30 "Bijaw" Chain Pipe Wrench

|

| 956,259 |

G. Amborn | 02/11/1908 | 04/26/1910 |

"Ratcho" Open-End Wrench

Williams "Ratcho" Open-End Wrench

|

| D46,260 |

C.A. Martin | 06/04/1914 | 08/11/1914 | Spanner Wrench |

| D46,782 |

F.W. Trabold | 10/23/1914 | 12/15/1914 |

Automobile Tire Tool |

| 1,239,459 |

A.F. Carew | 11/30/1915 | 09/11/1917 | Tool and Tool Holder |

| 1,327,309 |

G.W. Bufford | 03/14/1918 | 01/06/1920 | Chain Pipe Wrench |

| 1,778,748 |

L.G. Bayrer | 04/14/1923 | 10/21/1930 | Pipe Wrench |

| 1,787,787 |

W.C. Kress | 07/24/1925 | 01/06/1931 | Pipe Vise |

| 1,810,108 |

W.C. Kress | 08/22/1929 | 06/06/1931 | Holder for Wrench Set |

| 1,811,137 |

W.C. Kress | 01/15/1930 | 06/23/1931 |

Multi-Socket Wrench

Williams No. 1999 Multi-Socket Wrench

|

| 1,889,203 |

W.C. Kress | 06/14/1929 | 11/29/1932 |

Holder for Wrench Set |

| 1,954,820 |

W.C. Kress | 09/20/1932 | 04/17/1934 | Wrench

Williams S-20C Sliding Tee Handle

|

| 1,957,462 |

W.C. Kress | 01/25/1933 | 05/08/1934 |

Ratchet Wrench

Williams S-51 Ratchet

|

| 2,071,543 |

W.C. Kress | 09/14/1933 | 02/23/1937 |

Revolving Grip Handle

Williams NM-110 Drive Handle

|

| 2,097,594 |

W.C. Kress | 05/18/1936 | 11/02/1937 | Reversible Ratchet Wrench |

| 2,112,840 |

F.A. Haist | 05/08/1935 | 04/05/1938 |

Method of Making Adjustable Wrenches

Williams AP-8 Adjustable Wrench

|

| 2,167,720 |

W.C. Kress | 03/18/1937 | 08/01/1939 | Torque Indicating Wrench |

| 2,407,558 |

W.C. Kress | 11/16/1944 | 09/10/1946 | Ratchet Adapter |

| 2,444,135 |

W.C. Kress | 01/31/1944 | 06/29/1948 | Worm Joint Pliers |

| 2,600,617 |

C.F. Coates | 12/01/1948 | 06/17/1952 |

Adjustable Crowfoot Wrench

Williams SC-8 Adjustable Crowfoot

|

| 2,719,449 |

W.J. Johnson | 07/27/1953 | 10/04/1955 |

Adjustable Wrench Locking Mechanism

Williams APL-6 Adjustable Wrench

|

| 2,772,763 |

W.J. Johnson | 01/12/1951 | 12/04/1956 |

Dual-Pawl Ratchet Mechanism

Williams S-52 Ratchet

|

Trademarks

Williams registered a number of trademarks,

including the

W-Diamond logo,

"Williams",

"Agrippa",

"Vulcan",

"Superrench",

and "Superratchet".

Information on some of the more important trademarks is summarized in the table below.

J.H. Williams & Co.: Trademarks Issued

| Text Mark or Logo |

Reg. No. |

First Use | Date Filed | Date Issued |

Notes |

| W & D [diamond logo] |

10,235 |

| 04/07/1883 | 05/01/1883 |

Drop forgings.

"W & D" in a diamond logo.

Williams & Diamond in Flushing, New York.

Volume 23, page 1626.

|

| W [diamond logo] |

11,905 |

| 05/02/1884 | 02/03/1885 |

Drop forgings.

"W" in a diamond logo.

J.H. Williams & Company in Flushing, New York.

Volume 30, page 348.

|

| Vulcan |

34,514 |

05/01/1899 | 03/20/1900 | 04/17/1900 |

Pipe wrenches.

Renewed 04/17/1930.

|

| Vulcan |

34,562 |

05/01/1899 | 03/20/1900 | 04/24/1900 |

Drop forgings.

|

| Vulcan |

42,226 |

06/01/1897 | 01/23/1904 | 03/08/1904 |

Pipe wrenches and pipe vises.

|

| [Oval logo] |

80,202 |

| 06/10/1910 | 11/15/1910 |

Metal forgings.

Oval logo.

Serial 50,325. Published 09/13/1910. Renewed 11/15/1950.

|

| Vulcan |

88,987 |

01/01/1884 | 04/05/1912 | 10/29/1912 |

|

| Superjustable |

152,551 |

05/13/1921 | 07/14/1921 | 02/28/1922 |

For clamps |

|

104,112 |

01/01/1884 | 04/05/1912 | 04/27/1915 |

W-Diamond logo.

Company address in Brooklyn. |

| WILLIAMS |

|

01/01/1883 | 06/30/1921 | |

Wrenches, vises, other tools.

"WILLIAMS" in block text.

Serial 149,873. Published 07/24/1923.

|

| Superrench |

209,075 |

10/10/1925 | 10/20/1925 | 02/16/1926 |

|

|

230,447 |

11/09/1924 | 07/27/1925 | 07/19/1927 |

Wrenches and other tools.

Williams underline logo.

Serial 217,975. Company address in Buffalo.

|

| VOLUME |

256,651 |

01/15/1929 | 01/25/1929 | 05/21/1929 |

For wrenches and wrench holders.

"VOLUME" in block text.

Serial 278,449. Published 03/12/1929.

|

| Bantam |

277,308 |

06/10/1930 | 07/15/1930 | 11/11/1930 |

For wrenches, wrench sets, sockets and handles.

First-use date for wrench sets. Others July 8, 1930.

Published 09/02/1930. Serial 303,522.

|

| Midget |

277,309 |

05/17/1928 | 07/15/1930 | 11/11/1930 |

For wrenches, wrench sets, sockets and handles.

First-use date for wrench sets. Others July 8, 1930.

Published 09/02/1930. Serial 303,521.

|

| Supersocket |

283,105 |

12/13/1930 | 01/02/1931 | 05/19/1931 |

Wrenches, wrench sets, sockets, tool handles.

Serial 309,579. Published 03/03/1931.

|

| TWINHEX |

|

06/09/1931 | 06/26/1931 | |

Wrenches, wrench sets, sockets, tool handles.

Serial 316,352. Published 08/04/1931.

|

| Superratchet |

303,210 |

09/19/1932 | 10/07/1932 | 05/16/1933 |

Wrenches, wrench sets, sockets, tool handles.

Serial 331,072. Published 03/07/1933.

|

| Superhandle |

|

09/03/1936 | 09/29/1936 | |

Tool handles.

Serial 383,793. Published 04/20/1937.

|

| Superjaw |

344,774 |

09/03/1936 | 09/29/1936 | 04/06/1937 |

Jaws for tongs and pipe vises.

Serial 383,794. Published 01/26/1937.

|

| Supertong |

344,775 |

09/03/1936 | 09/29/1936 | 04/06/1937 |

Tongs and pipe vises.

Serial 383,795. Published 01/26/1937.

|

| Measurrench |

370,819 |

07/15/1938 | 08/11/1938 | 09/05/1939 |

Wrenches, wrench sets, sockets.

Serial 409,496.

|

| Williams |

381,837 |

01/01/1900 | 06/04/1940 | 10/08/1940 |

|

W-Diamond Logo

The scan in Fig. 12B shows

the W-Diamond logo as presented for trademark #104,112.

This logo was typically stamped on or forged into tools made by J.H. Williams.

AZ-Circle Logo

During the 1950s and 1960s J.H. Williams supplied adjustable wrenches to Sears Roebuck

for their Craftsman line.

These wrenches were stamped with an "AZ" manufacturer's code,

as seen at the left.

Fig. 12C shows

the AZ-Circle logo.

Manufacturing Dates

Williams tools are generally not marked with a date code or other explicit indication

of the manufacturing date.

When an estimate of the manufacturing date is needed,

it will have to be based on other information such as company name markings,

tool design style, patent markings, and other factors.

In order to assist with estimating manufacturing dates,

we hope to develop some guidelines based on tool markings and other characteristics.

For now, the following list of events and observations may be helpful in determining the

manufacturing date for some tools.

-

W-Diamond Logo.

The Williams W-Diamond logo was registered as a trademark, with the first use listed as 1884.

-

Buffalo Factory.

Williams built a new factory in Buffalo (New York) in 1914.

Since tools were then being made in two locations,

it's likely that Williams introduced slightly different face markings to distinguish production at

Brooklyn from production at Buffalo.

-

Brooklyn Marking.

The company moved its headquarters from Brooklyn to Buffalo some time after 1919.

-

Williams Scroll Logo.

The Williams name underlined by the "S" was registered as a trademark, with the first use listed as 1924.

The initial use on wrench faces included a W-Diamond logo below the scroll,

with "Forged in U.S.A." or similar text.

-

Superrench Trademark.

The "Superrench" trademark was filed in 1925 with a first-use date of October 10, 1925.

-

Across-Flats Sizes for Wrench Openings.

Until about 1927 Williams generally marked wrench openings with the nominal bolt size,

using the older U.S.S., S.A.E., or other appropriate size convention.

With the adoption of the American Standard system of sizing,

wrench openings were marked with the fractional across-flats size.

-

Chrome-Plated Finishes.

The "Superrench" line initially offered a nickel plated finish,

but by November of 1927 the standard finish was chrome plating over nickel.

-

"Chrome Alloy" Marking.

In the 1930s Williams began changing its alloy markings to a more generic "Chrome Alloy",

even while continuing to use chrome molybdenum steel for most of its production.

By around 1935 it's likely that most forged-in markings had been updated to "Chrome Alloy".

We have an extensive discussion of this in the section below on

Alloy Specifications and Markings.

-

Transitional Duohex-Box Markings on Angled Box Wrenches.

Angled box wrenches were introduced in 1937 and initially carried a transitional form of marking

derived from the earlier Duohex-Box wrenches.

By 1940 the standard marking for oval-shank box wrenches was likely in use.

-

NX Series of 1 Inch Drive Tools.

In the late 1930s Williams introduced 1 inch (square) drive tools in the NX series,

a replacement for older hex drive tools.

-

NM Series of 1/4-Drive Tools.

In 1940 Williams introduced 1/4-drive tools in the NM- series as a replacement for 9/32 drive.

-

Oval-Shank Box Wrenches.

By 1940 Williams was producing box wrenches in the oval-shank style with the standard markings.

-

Cadmium, Painted, or Plain Finish During Wartime Years.

Due to material shortages during the 1941-1945 wartime years,

the standard chrome plated finishes were replaced with cadmium plated, painted, or plain steel finishes.

-

Rough Surface Finish on Wrench Faces During Wartime Years.

Williams generally applied grinding and polishing operations to wrench faces prior to plating.

During the 1941-1945 wartime years these final finishing steps were sometimes omitted,

leaving the wrench faces with obvious lines from the last machining or grinding step.

This type of rough machined surface can be easily distinguished from the random pitted surface

caused by extensive rusting.

An good example of the rough surface finish is provided by the

Williams 1725B Open-End Wrench.

-

Alloy Marking on "Superrench" Tools.

In 1942 or soon thereafter Williams began using the "Alloy" marking for some tools,

instead of the earlier "Chrome-Molybdenum" or "Chrome-Alloy" markings.

This change was probably made due to material shortages during the wartime years,

but shortly after the war Williams stopped mentioning specific alloys in its catalogs.

We have a more extensive discussion of this in the section below on

Alloy Specifications and Markings.

-

"Williams U.S.A." Logo on Wrench Faces.

Around 1947 the wrench face markings were updated to use the Williams scroll with "U.S.A." below,

replacing the older W-Diamond logo.

The W-Diamond logo continued to be marked on some tool shanks,

and on smaller wrenches faces when the full Williams name wouldn't fit.

-

Double-Groove Style for Sockets.

The double-groove style for sockets

(see for example the 1/2-Drive Double-Groove Sockets)

was introduced around 1948.

-

Ribbed-Style Open-End Wrenches.

The "ribbed" style for open-end wrenches was introduced in 1952.

This style remained in use until 1959,

when it was replaced by the flat shank style.

-

Raised Panels on Wrenches.

The raised-panel wrench style was introduced in the mid 1950s,

some time after the 1952 advent of the ribbed style.

This style remained in use until 1959 for combination wrenches and until 1960 for box-end wrenches.

-

Flat Shanks on Wrenches.

The wrench style with flat shanks was introduced in 1959 for open-end and combination wrenches,

and by 1960 for other wrench types.

-

Cross-bar Holes with 1/2-Drive Deep Sockets.

The SD-12xx series deep sockets were fitted with cross-bar holes until at least the mid 1950s,

but by 1960 cross-bar holes had been discontinued.

-

Cold-formed Sockets.

By 1968 Williams was using a cold-forming process (called "Impact Extruded" in the catalog)

for making most sockets in 3/8 through 1 inch drive sizes.

Some sockets may have been cold-formed as early as 1960.

Face Markings on Wrenches

Williams changed the style of the face markings on its wrenches several times over the years,

and these markings therefore provide an approximate guide to the manufacturing date.

Fig. 13 shows

an example of one of the earliest face markings,

consisting the text "J.H. Williams & Co." and "Bklyn, N.Y. U.S.A.",

typically stamped on the face of a wrench.

Tools bearing this face marking generally also have a

W-Diamond logo forged into the shank.

This marking is believed to have been used on early production,

when the Brooklyn address referred to both the company's headquarters

and its principal factory location.

This mark will be referred to in the text as the Early Brooklyn face marking.

Fig. 14 shows

the first of a pair of similar markings,

consisting of an oval outline with the text

"J.H. Williams & Co." and "Brooklyn, U.S.A.",

with the W-Diamond logo in the center.

On smaller tools,

the text was generally abbreviated to fit in the available space.

The Brooklyn address suggests that this marking was used distinguish production in the Brooklyn factory,

with the other oval logo indicating the Buffalo factory.

Williams built its Buffalo factory in 1914,

and the oval logos are believed to have been used from around 1914 until 1924.

This mark will be referred to in the text as the JHW-Brooklyn face marking.

Fig. 15 shows

the very similar oval outline with the text

"J.H. Williams & Co." and "Forged in U.S.A.",

again with the W-Diamond logo in the center.

This marking was likely used to distinguish production at the Buffalo factory

(or other facilities) from the main Brooklyn factory and headquarters (see previous figure).

Williams built its Buffalo factory in 1914,

and the oval logos are believed to have been used from around 1914 until 1924.

This mark will be referred to in the text as the JHW-Forged face marking.

Around 1924 Williams updated its wrench face markings to the style shown at the left.

The Williams name is underlined by a scroll from the terminal "S",

and the text "Forged in U.S.A." appears below,

with the W-Diamond logo in the center.

The 1924 date is based on the trademark registration for the Williams name with the scroll underline,

which lists 1924 as the first use date.

Several alternate forms of this style were used for smaller tools with insufficient space

for the full "Forged in U.S.A." text.

These alternates (in order of decreasing size) were "Made in U.S.A.",

then "Made U.S.A.",

and finally just "U.S.A." for the smallest tools.

By 1947 Williams had updated its wrench face markings to the simpler style

shown in Fig. 17 at the left.

The Williams name remained underlined by a scroll,

but the text below was simply "U.S.A." without the W-Diamond logo.

(This example is highly polished,

and the reflection made it a bit difficult to photograph.)

This style of marking was generally used on wrench faces from about 1947 until

around 1955,

after which the adoption of the ribbed wrench style forced the markings to move to the shank.

This marking was also used on tools without a well-defined "face",

being placed on the shank or some other part of a tool.

We'll refer to this as the "Williams U.S.A." marking in the text.

Alloy Specifications and Markings

One slightly puzzling aspect of the Williams "Superrench" line is the variation in the

markings for alloy content.

The wrenches believed to be of the earliest production are invariably marked "Chrome-Molybdenum"

(or equivalent),

but tools of possibly later production are sometimes marked "Chrome-Alloy" or simply "Alloy".

When we first noticed the variation in markings,

we had hoped that this would provide a simple means of estimating the manufacturing date.

After extensive analysis of the markings,

we can show that in certain cases the alloy markings do provide some information on the production date.

To begin researching this issue,

we first did a quick review of the alloy composition noted in various Williams catalogs,

and have summarized the observations in the table below.

Note that the table reflects only what was printed in the catalogs,

not necessarily what was marked on (or used for) the tools themselves.

Catalog Specification of Alloy Steel For Selected Years

| Tool Category | 1927 | 1931 | 1933 | 1937 | 1940 | 1945 | 1947+ |

| Open-End Wrenches |

Cr-Mo | Cr-Alloy | Cr-Alloy | Cr-Mo | Cr-Mo | Cr-Mo | Alloy |

| Tappet Wrenches |

Cr-Mo | Cr-Alloy | Cr-Alloy | Cr-Mo | Cr-Mo | Cr-Mo | Alloy |

| Obstruction Wrenches |

Cr-Mo | Cr-Alloy | Cr-Alloy | Cr-Mo | Cr-Mo | --- | --- |

| Waterpump Wrenches |

--- | Cr-Alloy | Cr-Alloy | Cr-Mo | Cr-Mo | Cr-Mo | --- |

| Box-End Wrenches |

--- | Cr-Alloy | Cr-Alloy | Cr-Mo | Cr-Mo | Cr-Mo | Alloy |

| Combination Wrenches |

--- | --- | --- | --- | Cr-Alloy | Cr-Alloy | Alloy |

| Sockets |

--- | Cr-Alloy | Cr-Alloy | Cr-Mo | Cr-Mo | Cr-Mo | Alloy |

Several comments are worth noting here.

Our first observation is that the stated alloy composition is consistent across

all types of tools for a given catalog edition,

with the exception of the early combination wrenches.

This suggests that if changes in the alloy usage were going to be made for a particular year,

the change was made across the board.

Secondly, note that for 1947 (and later) no specific guidance is provided for

the alloy composition;

the catalogs simply note the use of "Selected Alloy Steels".

This gave Williams the maximum flexibility to match their alloy steel usage with

engineering requirements (or market conditions) as needed.

Our last observation is that (obviously) chrome-molybdenum steel is a chrome alloy,

and a wrench marked "Chrome Alloy" and made of chrome-moly steel has met its specification.

We can extend this discussion by asking a trick question:

is chrome-nickel-moly steel a chrome-molybdenum alloy?

A "yes" answer might argue that since a chrome-nickel-moly alloy does contain chromium and molybdenum,

it's also a chrome-molybdenum alloy.

But chrome-molybdenum has a degree of specificity to it and identifies a class of alloys such as AISI 4140,

whereas chrome-nickel-molybdenum identifies a different class of alloys,

such as AISI 8640, 8740, and 8742.

All of these alloys have highly desirable properties for toolmaking,

but there may be engineering or economic reasons for choosing one over the others.

If Williams generally intended to use chrome-moly steel,

but wanted flexibility to substitute chrome-nickel-moly or even chrome-vanadium steel,

a chrome-alloy marking would cover all cases.

We actually tested some Williams wrenches for alloy content and found that an early wrench marked "Chrome-Molybdenum"

had a composition similar to AISI 4140 chrome-moly steel,

while two later wrenches marked "Alloy V" were similar to AISI 8640 chrome-nickel-moly steel.

(See our article on Alloy Steels for discussion of the testing.)

Thus it's possible that Williams may have had discussions of this sort internally and decided

in favor of a more generic marking.

After reviewing the catalog information,

the next step should be to compare the actual markings on tools with the printed specifications.

This would be easy if Williams tools were marked with date codes,

but without date codes it's generally not possible to determine the manufacturing date with sufficient precision.

However, it turns out that a small number of tools have markings or other features

to provide a relatively precise estimate of the manufacturing date.

The list below summarizes the special cases we've identified so far,

and hopefully others will be found as well.

- Patent Pending Markings on Obstruction Wrenches.

Obstruction wrenches were first offered in the mid 1920s,

and some of these tools are stamped with a "Pat. Pendg" notation.

The earliest catalogs also mention the patent pending status,

but later catalogs (after the 1920s) no longer mention a patent.

Hence it's reasonable to assume that the wrenches with the patent notice are from the mid 1920s,

and all of the available examples are marked "Chrome-Molybdenum".

The examples include the

Williams 2021 Obstruction Wrench

and

Williams 2027C Obstruction Wrench.

- Patent Notice on Waterpump Wrenches.

Waterpump wrenches were introduced in the early 1930s,

and some examples are known to be marked with a patent notice for the Gillett 1929 patent

#RE17,417.

This patent is also noted in catalogs from 1931 and 1933,

but not in catalogs from 1937 and later.

It's reasonable to assume that the patent-marked waterpump wrenches are from the early 1930s,

and all of these wrenches are marked "Chrome-Molybdenum".

See for example the

Williams 8962 Waterpump Wrench.

- Transitional "Duohex-Box" Marking on Oval-Shank Wrenches.

Angled box wrenches with the oval shank style were introduced around 1937,

and some examples of these wrenches have been found with a "Duohex-Box" transitional marking.

The modern box wrench marking was introduced around 1940,

so that the examples with transitional markings were likely made from 1937-1939.

An example of a transitional wrench can be seen as the

Williams 7025 "Duohex-Box" Wrench.

Of the transitional wrenches examined so far,

four out of six are stamped "Chrome-Alloy",

and the other two have no alloy markings.

Significantly, none of them are marked "Chrome Molybdenum",

although chrome moly steel was standard during the time these wrenches were made.

- Cadmium or Plain Finish on Oval-Shank Wrenches.

The standard chrome-plated finish was generally replaced by cadmium, plain,

or painted finishes during the wartime years of 1942-1945.

Numerous examples of oval-shank wrenches with cadmium or similar finishes have been found,

and almost all of these have been stamped "Alloy Steel".

Examples include the

Williams 7721 Box Wrench,

Williams 4731A Box Wrench,

and

Williams 4731B Box Wrench.

- Review of Markings on Oval-Shank Wrenches.

A review of the markings on all 29 examples of oval-shank box wrenches in our collection (at that time)

found that all except for three were marked "Alloy Steel".

The three exceptions were marked "Chrome-Alloy".

- Cadmium or Plain Finish on Open-End Wrenches.

As noted above,

during the 1942-1945 wartime years chrome finishes were generally replaced by

cadmium, plain, or painted finishes.

A number of examples of the open-end "Superrench" series have been found with cadmium or similar finishes,

and the majority of these are marked with "Alloy" forged into the shank,

but with some examples marked "Chrome-Alloy" being noted as well.

Examples include the

Williams 1725B Wrench (Painted),

Williams 1725B Wrench (Plain),

Williams 1027 Wrench,

Williams 1029 Wrench (Painted),

Williams 1029 Wrench (Plain),

Williams 1029 Wrench,

and

Williams 1034A Wrench (Plain).

Significantly, no examples of apparent wartime production have been found with "Chrome Molybdenum" markings.

Since open-end wrenches of this era had forged-in markings,

this implies that Williams had already converted its forging dies to "Chrome Alloy" prior to the wartime era.

- Late Production of Angle-Head Obstruction Wrenches.

Production of angle-head obstruction wrenches was discontinued around 1945.

We have one example of an obstruction wrench that appears to be of mid 1940s production,

based on its gray-green powder-coat finish instead of the standard chrome plating.

This wrench has a forged-in "Alloy" marking on the shank,

and can be seen as the

Williams 2033A Obstruction Wrench.

- Williams U.S.A. Face Marking.

In 1947 Williams updated the face markings on wrenches to use the "Williams U.S.A." logo

instead of the older W-Diamond logo.

Based on our catalog review,