Automotive Specialty Tools

Special-Purpose Wrenches

Among the most common specialty tools are wrenches in unusual shapes or configurations,

or with openings of unusual sizes.

The tools allow access to bolts that are difficult or impossible to reach with standard tools.

1959 Starter & Manifold Box-End Wrench

Fig. 468 shows

a Williams 1959 9/16x5/8 halfmoon box-end wrench,

a style designed primarily for starter and manifold service.

The shank has stamped markings for the

W-Diamond logo and

"Superrench" trademark,

with "Chrome-Alloy" stamped on the back side.

The shank also has a forged-in code "JZ.." visible at the right

and as a close-up in the lower inset.

The model 1959 wrench is not listed in the 1933 Williams catalog,

but is shown in a 1937 A-409 update catalog,

where it is recommended for starter and manifold nuts.

The distinctive forged-in code on this example is of particular interest,

as it positively identifies the wrench as production by

Bonney Forge & Tool,

making this an uncommon example of contract production for Williams.

The forged-in code is actually the

Bonney Date Code for the wrench,

and in this case the code indicates a manufacturing date of 1934.

The equivalent Bonney tool is the model 2881 wrench,

which at that time would have been marked with "Bonney" and "Chrome Vanadium" forged into the shank.

A close look at the Williams photograph shows that the shank has been ground flat

on either side of the stamped markings,

in order to remove the original forged markings.

1960 Starter & Manifold Box-End Wrench

Fig. 469 shows

a Williams 1960 9/16x5/8 halfmoon box-end wrench intended for starter and manifold service.

The shank has stamped markings for "Superrench" and the

W-Diamond logo,

with "Made in U.S.A." and "Alloy" on the back side.

The back side shank also has a small forged-in number "8742" shown in the left inset,

although the digits are blurred and difficult to read.

The model 1960 wrench is not listed in the 1937 catalog,

but is shown in the 1940 and later catalogs at least through 1950.

The wrench is recommended for starter and manifold nuts on Chrysler and Dodge automobiles,

and on DeSoto through 1940.

The forged-in "8742" marking indicates the use of AISI 8742 steel,

an alloy with nickel, chromium, and molybdenum frequently used tool applications.

The "8742" marking (or other numbers for similar steels) has been observed fairly frequently on Herbrand tools,

suggesting that this wrench may have been made for Williams by Herbrand.

The Herbrand 2146 Starter and Manifold Wrench

is very similar in design to this example,

and other Herbrand half-moon wrenches such as the

Herbrand 1940 Wrench

have been noted as using AISI 8742 steel.

S-231 7/16x7/16 Double-Ended Hex Socket Wrench

Fig. 470 shows

a Williams S-231 7/16x7/16 double-ended hex socket wrench,

stamped "Superrench" and "Forged in U.S.A." with the

W-Diamond logo.

The wrench has an overall length of 11.2 inches,

with a length of 10.6 inches for the long arm.

The finish is chrome plating with polished sockets.

SV-244 1/2x1/2 Single-Offset Box Wrench

Fig. 471 shows

a Williams SV-244 1/2x1/2 single-offset box wrench with a round shank,

stamped "Superrench" and "Forged in U.S.A." with the

W-Diamond logo.

The overall length is 9.3 inches and the offset depth is 2.3 inches.

The finish is chrome plating.

The 1937 Williams catalog listed this as a new wrench model for servicing the

distributor on 1937 Ford V-8 automobiles,

and later catalogs (through 1945) listed it for 1937-1942 Ford and Lincoln Zephyr automobiles.

This particular example has a transitional marking style between the older Duo-Hex and later oval style

box wrenches,

suggesting a production date from 1937-1939.

1981 Double-Ended Hex Socket Wrench

Fig. 472 shows

a Williams 1981 9/16x9/16 double-ended hex socket wrench,

intended primarily for connecting-rod service on Ford V8 engines.

The shank is stamped "Chrome-Molybdenum" on one side,

with the "Superrench" trademark and

W-Diamond logo on the back side.

The wrench has an overall length of 12.0 inches,

with a length of 11.5 inches for the long arm.

The finish is chrome plating with polished sockets.

The model 1981 wrench has an interesting history.

This model was available as early as 1931 in a slightly shorter version with a 10 inch arm,

and at that time was described as a brake wrench for Bendix brakes.

By 1937 the arm length had been increased to 11.5 inches and the model number updated to 1981-A,

with the primary application listed as servicing connecting rods for Ford V8 engines.

The catalog illustration at that time shows the sockets with a distinctive tapered form.

The present example is unusual in bearing the older model number but with the later specifications,

suggesting a likely production date in the mid 1930s.

1021S 1/4x5/16 Brake Wrench

Fig. 459 shows

a Williams 1021S 1/4x5/16 brake wrench,

stamped "U.S.A." with the Williams logo on the face.

The shank is marked with the "Superrench" trademark forged into the front,

with "Alloy" and a "II" code forged into the back side.

The overall length is 4.5 inches,

and the finish is chrome plating with polished faces.

1731BR 3/4x7/8 Brake Wrench

Fig. 459B shows

a Williams 1731BR 3/4x7/8 brake wrench,

stamped "Forged in U.S.A." with the

W-Diamond logo on one face.

The shank is marked with the "Superrench" trademark forged into the front,

with "Alloy" and a "II" code forged into the back.

The overall length is 15.0 inches,

and the finish is chrome plating with polished faces.

1516 "Steeldraulic" Brake Pliers

Fig. 460 shows

a pair of Williams 1516 "steeldraulic" brake pliers,

marked with "U.S.A." and the

W-Diamond logo forged into the handle.

The overall length is 4.8 inches,

and the finish is chrome plating.

The inset shows the stop-boss forged into one handle,

to limit the closing travel.

1983 3/16x1/4 Brake Wrench

Fig. 461 shows

a Williams 1983 3/16x1/4 brake wrench,

stamped "U.S.A." with the

W-Diamond logo on one face,

with the model number on the other end (see lower inset).

The shank is marked with the "Superrench" trademark in forged raised letters,

with "Alloy" and a "V" code on the back side.

The overall length is 9.0 inches,

and the finish is gray paint.

1984X 7/16x1/2 Double-Square Brake Wrench

Fig. 462 shows

a Williams 1984X 7/16x1/2 double-square box wrench for Ford brake service.

The wrench is marked with the "Superrench" trademark forged into the shank,

with "Made U.S.A." and the

W-Diamond logo stamped at the left.

The back side is marked with "Chrome-Molybdenum" forged into the shank,

with the fractional sizes stamped at each end (see lower inset).

The overall length is 11.3 inches,

and the finish is chrome plating.

This wrench was designed to service the brakes on Ford model "A" cars and model "AA" trucks.

Similar wrenches were available from a number of other manufacturers,

and examples can be seen as the

Bonney 2857 Brake Wrench,

Duro-Chrome 268 Brake Wrench,

and

Herbrand 2333 Brake Wrench.

1985 5/8 Short Brake Wrench

Fig. 463 shows

a Williams 1985 5/8 short brake wrench,

stamped "Made U.S.A." with the

W-Diamond logo on the face (upper inset),

with the model number and size on the opposite face.

The shank is marked with the "Superrench" trademark in forged raised letters,

with "Chrome-Molybdenum" on the back side.

The overall length is 3.4 inches,

and the finish is chrome plating with polished faces.

1990 5/8x5/8 Brake Wrench

Fig. 464 shows

a Williams 1990 5/8x5/8 brake wrench,

stamped "Chrome-Molybdenum" on the shank with the fractional sizes on the faces.

The back side (top inset) is stamped with the "Superrench" trademark on the shank,

with "Made U.S.A." and the

W-Diamond logo on the left face and

the model number on the right face.

The overall length is 6.3 inches,

and the finish is chrome plating with polished faces.

An earlier example of this model (prior to the advent of alloy steel) can be seen as the

Williams 990 Brake Adjustment Wrench.

1990 "Special" (A183907) 1/2x9/16 Brake Wrench

Fig. 465 shows

a Williams 1990 "Special" 1/2x9/16 brake wrench with a dual marking as model A183907.

The face is stamped "Made U.S.A." with the

W-Diamond logo on one end,

with the standard 1990 model on the other end,

and the shank is stamped with "A183907" and the "Superrench" trademark.

The back side is stamped "Special" on the face with "Chrome-Alloy" on the shank.

The overall length is 6.3 inches,

and the finish is gray paint.

Currently we do not have any specific information for this wrench,

but believe that it's likely a military special order item from the early 1941-1942 wartime era.

The gray paint and semi-finished faces strongly suggest wartime production,

and the chrome alloy marking suggests the earlier years.

The A183907 marking is likely the model number for a specific maintenance tool.

The "Special" marking on this tool indicates a change from a standard tool.

The standard Williams 1990 model was a

Williams 1990 5/8x5/8 Brake Wrench

as seen in the previous figure.

1998A "Superrench" Brake Spoon

Fig. 466 shows

a Williams 1998A "Superrench" brake-adjusting spoon,

marked "Made U.S.A." with the

W-Diamond logo,

and with the "Superrench" trademark in raised letters.

The back side is marked "Chrome-Alloy" in raised letters,

as seen in the lower inset.

The overall length is 9.0 inches, and the finish is chrome plating.

1998B "Superrench" Brake Spoon

Fig. 467 shows

a Williams 1998B "Superrench" brake-adjusting spoon,

stamped with the "Williams U.S.A." logo and model number,

and with the "Superrench" trademark in raised letters.

The back side is marked "Alloy" in raised letters,

as seen in the lower inset.

The overall length is 7.9 inches,

and the finish is chrome plating.

No. 1999 "Multisocket" Eight-In-1 Socket Wrenches

The next several figures show examples of the Williams No. 1999 eight-way socket wrench,

a distinctive tool with rotating socket clusters on each end.

Fig. 473 shows

an earlier Williams No. 1999 eight-way socket wrench,

with "Williams Multisocket" and the

W-Diamond logo

forged into the shank.

The back side shank has forged-in markings "Forged in U.S.A." and "Chrome-Molybdenum",

plus a "Pat. Pendg." notice.

The socket sizes are 7/16, 1/2, 9/16, and 19/32 on the small head,

with 5/8, 11/16, 3/4, and 7/8 on the large head.

The sizes are marked on the edge of each opening,

as can be seen in the upper inset.

The overall length is 9.4 inches,

and the finish is chrome plating.

The chrome plating is unusual for this model,

as the Williams catalogs from 1931 through 1950 consistently report the finish

as cadmium plating.

The patent pending notice refers to patent

#1,811,137,

filed by W.C. Kress in 1930,

and issued in 1931 with assignment to J.H. Williams.

Fig. 474 shows

another example of the Williams No. 1999 wrench,

believed to be somewhat later than the previous figure.

The shank has forged markings "Williams Multisocket" with the

W-Diamond logo

and a small "T" code can be seen to the right of the logo.

The back side shank has forged-in markings "Drop-Forged in U.S.A." and "Chrome-Alloy Sockets",

plus a "Pat. Pend'g." notice.

The overall length is 9.3 inches,

and the finish is chrome plating.

The patent pending notice refers to Kress 1931 patent

#1,811,137.

The socket sizes are not marked on this example,

but the sizes are the same as in the previous figure.

Although the above two examples are very similar,

there are some differences worth noting.

The "Chrome-Molybdenum" marking on the first tool has become "Chrome-Alloy Sockets"

on the second,

suggesting that the specifications had been relaxed a bit.

Apparently only the sockets now needed to be chrome alloy,

and not necessarily chrome-molybdenum.

Other minor changes in markings -- the small "T" code,

and the use of "Drop-Forged in U.S.A." instead of "Forged in U.S.A." --

indicate at least that the forging dies had been updated,

possibly for use at a different factory.

More significant though is the detail that didn't change:

even though these examples were probably made some years apart,

both are still marked with a patent pending status.

Typically a company would mark their products "Patented" after the patent had been issued,

possibly with a patent date or number as well.

But after reviewing these examples,

plus photographs of perhaps ten additional examples of the No. 1999 wrenches,

all of them were marked with the "Pat. Pendg." notation.

No. 1999 "Multisocket" Eight-In-1 Socket Wrench, Raised Panel Version

In the 1950s Williams redesigned the Multisocket wrench with a raised panel forging,

similar to the stylistic make-over given to the other wrench lines.

Fig. 475 shows

a Williams No. 1999 eight-way socket wrench in the raised panel style,

stamped "J.H. Williams & Co." and "Forged U.S.A." on the raised panel,

with "Multisocket" on the back side.

As with the earlier models,

the socket sizes are 7/16, 1/2, 9/16, and 19/32 on the small head,

with 5/8, 11/16, 3/4, and 7/8 on the large head.

The overall length is 9.9 inches,

and the finish is chrome plating.

No patent notice is marked on this example,

but the wrench follows the same design described by patent

#1,811,137.

The raised panels on this model first appeared in the 1950s,

probably around the same time as the paneled designs for the Superrench line.

Chrome plated finishes for this model were also introduced in the 1950s;

up until at least 1950,

the model 1999 wrenches were specified with cadmium plated finishes.

1997 "Superrench" Offset Screwdriver

Fig. 476 shows

a Williams 1997 offset screwdriver,

marked with the "Superrench" trademark and model number forged into one side,

with "Alloy" and the

W-Diamond logo forged into the back side.

A forged-in "V" code also appears on the back side shank.

The overall length is 6.0 inches,

and the finish is cadmium plating.

S-60C 1/2-Drive Stud Extractor

Fig. 478 shows

a Williams S-60C 1/2-drive stud extractor of the eccentric cam type,

marked "U.S.A." with the Williams logo.

The diameter of the body is 2.0 inches,

and the overall height is 2.5 inches.

The finish is chrome plating.

The right inset shows a top view of the body.

Two holes of different diameters are provided,

in order to handle studs of various sizes.

One interesting feature of this design is that the eccentric cam is secured to the drive shaft

only by a detent ball,

allowing it to be easily removed for cleaning or replacement.

Adjustable Wrenches

Although Williams had produced various types of adjustable wrenches early in its history,

the company waited until the mid 1930s to offer the popular Crescent-style adjustable wrenches.

The Williams adjustables closely resembled the Crescent-style wrenches from other tool companies,

but incorporated at least one significant change to the construction.

In the Williams adjustable wrenches,

the keyway for the sliding jaw (and the jaw itself) is made with a flat top,

instead of the typical rounded top.

The flat top helps to minimize lateral forces when under heavy load,

forces that could otherwise distort and damage the wrench.

This design is described by patent

#2,112,840,

filed by F.A. Haist in 1935 and issued in 1938.

The 1937 Williams catalog offers adjustable wrenches in both alloy steel and carbon steel,

and in sizes from 4 to 12 inches.

Williams used the trademark "Superjustable" for the alloy steel models,

while the carbon steel wrenches were marked "Williams' Adjustable".

(The "Superjustable" trademark was actually registered in the early 1920s,

but was used at that time for clamps rather than wrenches.)

By 1940 the Williams catalog had extended the available sizes up to 18 inches,

but interestingly the larger models were footnoted as being of "Diamond" brand,

a reference to the wrenches from the Diamond Calk Horseshoe Company.

The carbon steel models had been discontinued by 1945,

and by 1950 Williams had extended the available sizes up to 24 inches and brought the

production in-house.

In the 1950s Williams brought back the carbon steel adjustable wrench models,

using a slightly different design with a raised ring around the hanging hole.

These revised carbon-steel models were available only briefly though,

as by 1960 they had been superseded by an industrial finish version of the standard "Superjustable" line.

Apparently by this point in time the cost difference between carbon and alloy steel was not enough

to justify two separate product lines,

making it more attractive to offer two finish options.

By 1968 Williams had assigned model numbers to the Superjustable wrench series.

The standard chrome-plated wrenches were given an "AP" prefix followed by the nominal size,

for example AP-8 for an 8 inch wrench.

The industrial (black) finish models were given an "AB" prefix.

It appears that by this time the markings were stamped rather than forged-in,

so that the chrome and black models could be forged with the same dies.

Shortly after the advent of model numbers Williams made one further minor change

to the wrench design.

The hanging hole on wrenches 12 inches and under was given a raised ridge,

similar to what had been done for the second-generation carbon-steel models.

(Wrench sizes 15 inches and up were unchanged.)

The raised ridge is first illustrated in the catalogs around 1970,

though it's possible that the change occurred with the switch to stamped markings.

Early Adjustable Wrenches

Early Carbon Steel 8 Inch Adjustable Wrench

We'll begin this section with an example of the carbon steel adjustable (rather than "Superjustable") wrenches.

Fig. 479 shows

a Williams 8 inch adjustable wrench,

marked "Williams' Adjustable" with the

W-Diamond logo in forged raised letters,

with "J.H. Williams & Co." and "Forged in U.S.A." on the back side.

The top inset shows a side view of the wrench,

illustrating the general construction and the flat-topped keyway.

The overall length is 8.1 inches,

and the maximum opening is 1.0 inches.

The head thickness was measured at 0.55 inches.

The finish is plain steel.

Early "Superjustable" 4 Inch Adjustable Wrench

The next several figures show examples of early "Superjustable" wrenches.

Fig. 480 shows

an early Williams 4 inch adjustable wrench,

marked with "Superjustable" and "Alloy V" forged into the shank,

with "J.H. Williams & Co." and "Forged in U.S.A." forged into the back side.

The back side also has a forged-in

W-Diamond logo at the left.

The overall length is 4.2 inches with a maximum jaw opening of 0.5 inches.

The finish is plain steel,

with some pitting due to rust.

The W-Diamond logo on this example indicates a likely manufacturing date

in the range 1935-1947.

Early "Superjustable" 8 Inch Adjustable Wrench

Fig. 481 shows

an early Williams 8 inch adjustable wrench,

marked "Superjustable" with "Patd in U.S.A." and "Alloy" forged into the shank,

with the

W-Diamond logo

followed by "J.H. Williams & Co." and "Forged in U.S.A." forged into the back side.

The shank also has a "V" code stamped near the "Alloy" marking.

The top inset shows a side view of the wrench,

illustrating the relatively thin construction.

The overall length is 8.2 inches,

and the maximum jaw opening is 1.0 inches.

The head thickness was measured at 0.49 inches.

The finish is plain steel.

The patent notice refers to patent

#2,112,840,

filed by F.A. Haist in 1935 and issued in 1938.

The W-Diamond logo on this example indicates a likely manufacturing date

in the range 1935-1947.

Early "Superjustable" 10 Inch Adjustable Wrench

Fig. 482 shows

an early Williams 10 inch adjustable wrench,

marked "Superjustable" with "Patd in U.S.A." and "Alloy V" in raised letters.

The back side is marked with the

W-Diamond logo

followed by "J.H. Williams & Co." and "Drop-Forged in U.S.A.",

all in forged raised letters.

The top inset shows a side view of the wrench,

illustrating the relatively thin construction.

The head thickness was measured at 0.56 inches.

The overall length is 10.1 inches,

and the maximum jaw opening is 1.2 inches.

The finish was originally chrome plating,

but most has been lost due to extensive rust and pitting,

plainly visible in the photograph.

The patent notice refers to patent

#2,112,840,

filed by F.A. Haist in 1935 and issued in 1938.

The W-Diamond logo on this example indicates a likely manufacturing date

in the range 1935-1947.

Second-Generation Carbon Steel Adjustable Wrenches

In the 1950s Williams resumed production of carbon steel adjustable wrenches,

but in a slightly different design with a raised ring around the hanging hole.

These second-generation carbon-steel models were available only briefly though;

by 1960 they had been superseded by an industrial finish version of the standard

"Superjustable" line.

Later Carbon Steel 4 Inch Adjustable Wrench

Fig. 483 shows

an example of the later carbon steel models,

a Williams 4 inch adjustable wrench marked with "Adjustable" and "Patd. U.S.A." forged into the shank,

with "J.H. Williams & Co." and "Drop-Forged" on the back side.

The overall length is 4.3 inches,

and the maximum opening is approximately 0.5 inch.

The finish is plain steel.

The top inset shows a side view of the wrench,

illustrating the general construction and the flat-topped keyway.

The patent notice refers to patent

#2,112,840,

filed by F.A. Haist in 1935 and issued in 1938.

Later Carbon Steel 6 Inch Adjustable Wrench

Fig. 484 shows

a later Williams 6 inch adjustable wrench,

marked with "Adjustable" and "Patd. U.S.A." forged into the shank,

with "J.H. Williams & Co." and "Drop-Forged" on the back side.

The overall length is 6.2 inches,

and the maximum opening is approximately 0.8 inch.

The finish is plain steel.

The top inset shows a side view of the wrench,

illustrating the general construction and the flat-topped keyway.

The patent notice refers to patent

#2,112,840,

filed by F.A. Haist in 1935 and issued in 1938.

Later Carbon Steel 8 Inch Adjustable Wrench

Fig. 485 shows

another second-generation carbon steel wrench,

a Williams 8 inch adjustable wrench.

The wrench is marked with "Adjustable" and "Patd. in U.S.A." forged into the shank,

with "J.H. Williams & Co." and "Drop-Forged" (partially obscured by a brazing accident)

forged into the back side.

The overall length is 8.2 inches,

and the maximum opening is approximately 1.0 inch.

The finish is plain steel.

The top inset shows a side view of the wrench,

illustrating the general construction and the flat-topped keyway.

The patent notice refers to patent

#2,112,840,

filed by F.A. Haist in 1935 and issued in 1938.

Later "Superjustable" Adjustable Wrenches

"Superjustable" 6 Inch Adjustable Wrench

Fig. 486 shows

another example of the Superjustable series,

a Williams 6 inch adjustable wrench,

marked "Superjustable" with "6 In." and "U.S.A." forged into the shank,

and with "J.H. Williams & Co." and "Forged Alloy" forged into the back side.

The overall length is 6.2 inches,

and the maximum jaw opening is 0.8 inches.

The finish is plain steel.

The plain hanging hole indicates production from 1947 to 1967.

"Superjustable" 10 Inch Adjustable Wrench

Fig. 487 shows

a Williams "Superjustable" 10 inch adjustable wrench,

marked "Superjustable" with "Patd. in U.S.A." and "10 In." forged into the shank,

with "J.H. Williams & Co." plus "Drop-Forged" and "Alloy =" forged into the back side.

The overall length is 10.2 inches and the maximum jaw opening is 1.2 inches.

The head thickness was measured at 0.58 inches.

The finish is chrome plating with highly polished faces.

The patent notice

refers to patent

#2,112,840,

filed by F.A. Haist in 1935 and issued in 1938.

This wrench was

acquired in nearly new condition in its original box.

Fig. 488 shows

the box for the Williams 10 Inch "Superjustable" wrench.

AP-4 4 Inch Adjustable Wrench

The next several figures show later examples of the Superjustable wrench line

with AP- or AB-series model numbers,

and with markings stamped instead of forged into the shank.

Fig. 489 shows

a Williams AP-4 "Superjustable" 4 inch adjustable wrench,

stamped "Superjustable U.S.A." on the front,

with "J.H. Williams & Co." on the back side.

The back side shank also has a forged-in "L" code near the hanging hole.

The overall length is 4.3 inches,

and the maximum opening is 0.5 inches.

The finish is chrome plating with polished faces.

Note that the hanging hole now has a raised ridge around it,

indicating production in 1968 or later.

AP-8 8 Inch Adjustable Wrench

Fig. 490 shows

a Williams AP-8 8 inch adjustable wrench,

stamped "Superjustable" and "Made in U.S.A." on the shank,

with "J.H. Williams & Co." and "Forged Alloy" on the back side.

The back side also has a forged-in code "L" near the hanging hole.

The overall length is 8.2 inches,

and the maximum opening is 1.0 inches.

The finish is chrome plating with polished faces.

The top inset shows a side view of the wrench to illustrate the slim profile.

The square shoulder of the sliding jaw can be seen on close examination.

AB-8 8 Inch Adjustable Wrench

Fig. 491 shows

a Williams AB-8 8 inch adjustable wrench,

stamped "Superjustable" and "Made in U.S.A." on the shank,

with "J.H. Williams & Co." and "Forged Alloy" on the back side.

The overall length is 8.2 inches,

and the maximum opening is 1.0 inches.

The finish is black oxide.

The thin profile of the wrench can be seen in the top inset,

and the maximum head thickness was measured at 0.49 inches.

Note also that the edge of the handle shows a ridge from the trimming operation,

a cost-saving measure appropriate for this industrial-finish model.

AP-10 10 Inch Adjustable Wrench

Fig. 492 shows

a Williams AP-10 10 inch adjustable wrench,

stamped "Superjustable" and "Made in U.S.A." on the shank,

with "J.H. Williams & Co." and "Forged Alloy" on the back side.

The back side also has a forged-in code "L" near the hanging hole.

The overall length is 10.2 inches,

and the maximum opening is 1.3 inches,

a fairly wide jaw opening for this wrench size.

The finish is chrome plating with polished faces.

AP-12 12 Inch Adjustable Wrench

Fig. 493 shows

a Williams AP-12 12 inch adjustable wrench,

stamped "Superjustable" and "Made in U.S.A." on the shank,

with "J.H. Williams & Co." and "Forged Alloy" on the back side.

The overall length is 12.2 inches,

and the maximum opening is 1.4 inches.

The head thickness was measured at 0.73 inches.

The finish is chrome plating with polished faces.

APL-6 Locking Adjustable Wrench

In addition to its basic models,

Williams offered a locking adjustable wrench based on a simple sliding pin mechanism.

An example of a locking model is shown in Fig. 494,

a Williams APL-6 6 inch adjustable wrench marked "Superjustable" and "Made in U.S.A." on the front,

with "J.H. Williams & Co." and "Forged Alloy" on the back side.

The back side also has a forged-in code "L" near the hanging hole.

The overall length is 6.1 inches,

and the maximum opening is 0.7 inches.

The finish is chrome plating with polished faces.

The locking mechanism is covered by patent

#2,719,449,

issued to W.J. Johnson in 1955.

Wartime Superrench Models

The Superrench tools shown in the previous sections have all been standard models

listed in the Williams catalogs,

with the exception of a few "Special" models made for particular customers.

But in addition to these standard models,

Williams also produced wrenches in at least two other Superrench lines,

a 3000-series of open-end wrenches and a 4000-series of angled box wrenches.

No catalog references are known for these alternate lines,

although enough examples have been found to suggest that they were produced in substantial quantities.

The 3000-series of open-end wrenches are basically very similar to the corresponding

standard 1000-series Superrench models,

and likewise the 4000-series of box wrenches are very similar to the corresponding

standard 7000-series Superrenches.

In both cases the major exception is that the alternate 3000 and 4000 series models are known

only with plain or cadmium finishes,

rather than the standard chrome plated finish.

The use of the plain or cadmium finishes suggests that these alternate models

were produced for special wartime contracts in the 1941-1945 time frame.

The use of alternate model numbers may have been due to slightly different specifications,

or perhaps the standard lifetime warranty was not extended to these tools.

3000-Series Open-End Wrenches

The 3000-series of open-end wrenches are nearly identical to the corresponding

standard 1000-series Superrench models,

but were produced only with cadmium or plain finishes.

3721 5/16x3/8 Open-End Wrench

Our first example of the 3000 series is shown in Fig. 495,

a Williams 3721 5/16x3/8 open-end wrench,

stamped "U.S.A." with the

W-Diamond logo on one face.

The shank has the "Superrench" trademark forged in raised letters,

with "Chrome-Alloy" in raised letters on the back side.

The overall length is 3.9 inches,

and the finish is cadmium plating,

though worn away in some areas.

3725 7/16x1/2 Open-End Wrench

The next several figures will show examples of the 3000 series open-end wrenches.

Fig. 496 shows

a Williams 3725 7/16x1/2 open-end wrench,

stamped "Made U.S.A." with the

W-Diamond logo on one face.

The shank has the "Superrench" trademark forged in raised letters,

with "Chrome-Alloy" in raised letters on the back side.

The overall length is 5.6 inches,

and the finish is plain steel.

3731 3/4x13/16 Open-End Wrench

Fig. 497 shows

a Williams 3731 3/4x13/16 open-end wrench,

stamped "Forged in U.S.A." with the

W-Diamond logo on one face.

The shank is marked with the "Superrench" trademark in forged raised letters,

with "Chrome-Alloy" forged into the back side.

The overall length is 9.2 inches,

and the finish is cadmium plating.

The "Chrome-Alloy" marking and plain finish suggest production during the earlier wartime years.

An example of the standard Superrench model for this size can be seen as the

Williams 1731 Open-End Wrench.

This wrench was one of a small number of tools that were tested for alloy content using an XRF machine.

The startling result showed that this wrench is actually made from a cobalt-nickel-molybdenum alloy,

rather than the chrome alloy promised by the forged-in marking!

This unexpected finding serves as the proverbial "smoking gun" to explain why tool markings were changed

to a generic "Alloy Steel" during the wartime years.

The interested reader can find more information at

Test Results for Williams 3731.

3033A 7/8x15/16 Open-End Wrenches

The next figures show two examples of the Williams 3033A model,

with minor differences in the markings.

Fig. 498 shows

a Williams 3033A 7/8x15/16 open-end wrench,

stamped "Forged in U.S.A." with the

W-Diamond logo on one face.

The shank has the "Superrench" trademark with "Chrome-Alloy" on the back side,

both in forged raised letters.

The overall length is 10.0 inches.

The finish is plain steel,

and the faces have been left with a rough finish as well.

Fig. 499 shows

a Williams 3033A 7/8x15/16 open-end wrench,

stamped "Forged in U.S.A." with the

W-Diamond logo on one face.

The shank is marked with the "Superrench" trademark in forged raised letters,

with "Alloy" on the back side.

The overall length is 9.9 inches,

and the finish is cadmium plating.

4000-Series Open-End Wrenches

The 4000-series of angled box-end wrenches are nearly identical to the corresponding

7000-series of Superrench box wrenches,

but were produced only with cadmium or plain finishes.

The known sizes range from the model 4721 (5/16x3/8) up to the 4040B (1-3/8x1-7/16),

but since no catalog references are available,

additional sizes may be found.

4721 5/16x3/8 Box-End Wrench

The next several figures will show examples of the 4000 series angled box wrenches.

Fig. 500 shows

a Williams 4721 5/16x3/8 box-end wrench with an oval shank,

marked "Williams Superrench" on the top line,

with "Forged in U.S.A." and "Chrome-Alloy" on either side of the

W-Diamond logo.

The overall length is 4.1 inches,

and the finish is plain steel.

The plain finish would suggest a likely manufacturing date during 1942-1945,

but the "Chrome-Alloy" marking suggests the earlier part of the range.

4723 3/8x7/16 Box-End Wrench

Fig. 501 shows

a Williams 4723 3/8x7/16 box-end wrench with an oval shank,

marked "Williams Superrench" on the top line,

with "Forged in U.S.A." and "Chrome-Alloy" on either side of the

W-Diamond logo.

The overall length is 4.6 inches,

and the finish is plain steel.

The plain finish would suggest a likely manufacturing date during 1942-1945,

but the "Chrome-Alloy" marking suggests the earlier part of the range.

4725B 1/2x9/16 Box-End Wrench

Fig. 502 shows

a Williams 4725B 1/2x9/16 box-end wrench with an oval shank,

marked "Williams Superrench" on the top line,

with "Forged in U.S.A." and "Chrome-Alloy" on either side of the

W-Diamond logo.

The overall length is 6.2 inches,

and the finish is plain steel.

The plain finish would suggest a likely manufacturing date during 1942-1945,

but the less common "Chrome-Alloy" marking suggests the earlier part of the range.

4727A 5/8x11/16 Box-End Wrench

Fig. 503 shows

a Williams 4727A 5/8x11/16 box-end wrench with an oval shank,

marked "Williams Superrench" on the top line,

with "Forged in U.S.A." and "Chrome-Alloy" on either side of the

W-Diamond logo.

The overall length is 10.3 inches,

and the finish is cadmium plate.

The cadmium finish would suggest a likely manufacturing date during 1942-1945,

but the less common "Chrome-Alloy" marking suggests the earlier part of the range.

4731A 3/4x7/8 Box-End Wrenches

The next figures show two generations of the Williams 4731A wrench.

Fig. 504 shows

an earlier Williams 4731A 3/4x7/8 box-end wrench,

stamped "Williams Superrench" on the top line of the shank,

with "Forged in U.S.A." and "Chrome-Alloy" on either side of the

W-Diamond logo.

The back side is stamped with the model number and fractional sizes.

The overall length is 12.3 inches,

and the finish is cadmium plating.

The cadmium finish indicates a manufacturing date during the 1942-1945 wartime years,

and the "Chrome-Alloy" marking suggests the earlier 1942-1943 years.

Fig. 505 shows

a slightly later Williams 4731A 3/4x7/8 box-end wrench,

stamped "Williams Superrench" on the top line of the shank,

with "Forged in U.S.A." and "Alloy Steel" on either side of the

W-Diamond logo.

A forged-in code "V" can be seen at the left end of the shank.

The overall length is 12.3 inches,

and the finish is cadmium plate.

The cadmium finish indicates a manufacturing date during the 1942-1945 wartime years,

and the "Alloy" marking suggests the later 1943-1945 years.

4731B 13/16x7/8 Box-End Wrenches

The next figures show two generations of the Williams 4731B wrench.

Fig. 506 shows

an earlier Williams 4731B 13/16x7/8 box-end wrench with an oval shank,

stamped with "Williams Superrench" on the top line,

with "Forged in U.S.A." and "Chrome-Alloy" on either side of the

W-Diamond logo.

The back side is stamped with the model number and fractional sizes.

The overall length is 13.3 inches,

and the finish is plain steel.

The plain finish would suggest a likely manufacturing date during 1942-1945,

but the less common "Chrome-Alloy" marking suggests the earlier part of the range.

Fig. 507 shows

a slightly later Williams 4731B 13/16x7/8 box-end wrench,

stamped with "Williams Superrench" on the top line,

with "Forged in U.S.A." and "Alloy Steel" on either side of the

W-Diamond logo.

A forged-in code "V" can be seen at the left end of the shank.

The overall length is 13.3 inches,

and the finish is cadmium plate.

The cadmium finish indicates a likely manufacturing date of 1942-1945,

and the "Alloy" marking suggests the later part of the range.

4038B 1-1/4x1-5/16 Box-End Wrench

Fig. 508 shows

a Williams 4038B 1-1/4x1-5/16 box-end wrench with an oval shank,

stamped on the shank with

"Williams Superrench" on the top line,

followed by "Forged in U.S.A." and "Chrome-Alloy" on either side of the

W-Diamond logo.

The back side is stamped with the model number and fractional sizes,

as shown in the lower inset.

The overall length is 18.4 inches,

and the finish is cadmium plating.

The cadmium finish suggests a likely manufacturing date during 1942-1945,

and the less common "Chrome-Alloy" marking suggests the earlier part of the range.

4739 1-1/4x1-3/8 Box-End Wrenches

The next figures show two generations of the 4739 box wrench.

Fig. 509 shows

an earlier Williams 4739 1-1/4x1-3/8 box-end wrench with an oval shank,

stamped on the shank with

"Williams Superrench" on the top line,

followed by "Forged in U.S.A." and "Chrome-Alloy" on either side of the

W-Diamond logo.

The back side is stamped with the model number and fractional sizes,

as shown in the lower inset.

The overall length is 19.3 inches,

and the finish is cadmium plating.

The cadmium finish suggests a likely manufacturing date during 1942-1945,

and the less common "Chrome-Alloy" marking suggests the earlier part of the range.

Fig. 510 shows

a somewhat later Williams 4739 1-1/4x1-3/8 box-end wrench with an oval shank,

stamped on the shank with

"Williams Superrench" on the top line,

followed by "Forged in U.S.A." and "Alloy Steel" on either side of the

W-Diamond logo.

The shank also has a forged-in code "V" visible at the left.

The back side is stamped with the model number and fractional sizes,

as shown in the lower inset.

The overall length is 19.3 inches,

and the finish is cadmium plating.

The cadmium finish indicates a likely manufacturing date of 1942-1945,

and the "Alloy Steel" marking suggests the later part of the range.

4040B 1-3/8x1-7/16 Box-End Wrench, Oval-Shank Style

Fig. 511 shows

a Williams 4040B 1-3/8x1-7/16 box-end wrench with an oval shank.

The shank is marked "Williams Superrench" on the top line,

with "Forged in U.S.A." and "Alloy Steel" on either side of the

W-Diamond logo.

A forged-in code "V" can be seen at the left end of the shank.

The overall length is 21.5 inches,

and the finish is cadmium plating.

The cadmium finish indicates a likely manufacturing date of 1942-1945,

and the "Alloy Steel" marking suggests the later part of the range.

Transitional Superrench Styles

The previous sections have introduced all of the major wrench types produced by Williams,

so in this section we'll look at primarily stylistic changes to the wrench designs in the 1950s.

The Ribbed Style

In 1952 Williams introduced a new "Streamlined" design for its open-end wrenches,

a somewhat odd but attractive style with raised ribs.

The handles were made narrower and thinner,

and raised and polished ribs extended part way down the shank before opening out at each end.

The ribs left only a small flat area around the middle of the shank,

so the markings were generally stamped here,

with the fractional sizes stamped on the faces.

However, a few examples have been found with the "Williams U.S.A." logo stamped on the face,

and these are believed to represent the earliest production.

The ribbed-style open-end wrenches were given the same (industry-standard) model numbers as

the previous wrench generation,

except that a few examples are known with an "A" prefix to the model number, e.g. A1725B.

Currently all of the available examples with the Williams logo stamped on the face also

have model numbers with the A-prefix,

leading to our current hypothesis that for the early production runs of the new style,

Williams had not yet decided that the new wrenches would replace the standard models.

Hence the early examples were marked with "alternate" A-prefix model numbers,

then later the markings were moved to the shank,

and finally the model numbers reverted to the older numbers.

Our first catalog reference for this style is from an edition of catalog A-50 printed in 1952,

and the description there refers to the new wrench design,

suggesting that 1952 is the likely date of introduction.

The other wrenches in the catalog were not yet illustrated in the raised-panel style,

so the ribbed design for open-end wrenches apparently preceded the design changes for other wrenches.

A somewhat later catalog No. 302 from around 1956 shows box-end and combination wrenches

with raised panels on the shank,

such as the

7725B Raised-Panel Box-End Wrench.

1020 1/4x5/16 Open-End Wrench, Ribbed Style

Our first (and smallest) example of the ribbed style is shown in Fig. 512,

a Williams 1020 1/4x5/16 open-end wrench,

stamped "U.S.A." with "Superrench" on the back side.

The overall length is 3.8 inches,

and the finish is chrome plating with polished ribs and faces.

A1721 5/16x3/8 Open-End Wrench, Ribbed Style

Fig. 513 shows

a Williams A1721 5/16x3/8 open-end wrench,

stamped with the "Williams U.S.A." logo on the shank,

with "Superrench" on the back side.

The front faces are stamped with the fractional sizes,

with the model number on the back side face.

The overall length is 4.3 inches,

and the finish is chrome plating with polished ribs and faces.

A1723 3/8x7/16 Open-End Wrench, Ribbed Style

Fig. 514 shows

a Williams A1723 3/8x7/16 open-end wrench in the ribbed style,

stamped with the "Williams U.S.A." logo on the shank,

with "Superrench" on the back side.

The shank also has a forged-in "B" code to the left of the Williams name.

The overall length is 4.7 inches.

The original chrome plated finish has been worn off,

with some traces of the copper underplating still present.

A1723A 3/8x1/2 Open-End Wrench, Ribbed Style

Fig. 515 shows

a Williams A1723A 3/8x1/2 open-end wrench in the ribbed style,

stamped with the "Williams U.S.A." logo on the shank,

with "Superrench" on the back side.

The overall length is 4.9 inches,

and the finish is chrome plating with polished ribs and faces.

[A]1725 7/16x1/2 Open-End Wrenches, Ribbed Style

The next two figures show the alternate (A-prefix) and standard versions of the 1725B model wrench.

Fig. 516 shows

a Williams A1725 7/16x1/2 open-end wrench in the ribbed style,

stamped with the "Williams U.S.A." logo on the shank,

with "Superrench" on the back side.

The overall length is 5.1 inches,

and the finish is chrome plating with polished ribs and faces.

Fig. 517 shows

a Williams 1725 7/16x1/2 open-end wrench in the ribbed style,

stamped with the "Williams U.S.A." logo on the shank,

with "Superrench" on the back side.

The shank also has a forged-in code "B" visible to the left of the Williams logo.

The overall length is 5.1 inches,

and the finish is chrome plating with polished ribs and faces.

[A]1725B 1/2x9/16 Open-End Wrenches, Ribbed-Style

The next two figures show the alternate (A-prefix) and standard versions of the 1725B model wrench.

Fig. 518 shows

a Williams A1725B 1/2x9/16 open-end wrench in the ribbed style,

stamped with the "Williams U.S.A." logo on the face,

and with "Superrench" on the shank.

The back side faces (not shown) are stamped with the fractional sizes.

The overall length is 6.3 inches,

and the finish is chrome plating with polished faces and ribs.

Fig. 519 shows

a later Williams 1725B open-end wrench in the ribbed style,

stamped with the "Williams U.S.A." logo on the shank,

with "Superrench" on the back side.

The overall length is 6.2 inches,

and the finish is chrome plating with polished faces and ribs.

1025 1/2x19/32 Open-End Wrench, Ribbed-Style

Fig. 520 shows

a Williams 1025 1/2x19/32 open-end wrench in the ribbed style,

stamped with the "Williams U.S.A." logo on the shank,

with "Superrench" on the back side.

The overall length is 6.2 inches,

and the finish is chrome plating with some loss due to rust.

1727 9/16x5/8 Open-End Wrench, Ribbed-Style

Fig. 521 shows

a Williams 1727 9/16x5/8 open-end wrench in the ribbed style,

stamped with the "Williams U.S.A." logo on the shank,

with "Superrench" on the back side.

The overall length is 6.8 inches,

and the finish is chrome plating.

A1027B 5/8x11/16 Open-End Wrench, Ribbed Style

Fig. 522 shows

a Williams A1027B 5/8x11/16 open-end wrench in the ribbed style,

stamped on the shank with the "Williams U.S.A." logo,

with "Superrench" on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side.

The overall length is 7.5 inches,

and the finish is chrome plating with polished ribs and faces.

An example of this model in a previous generation style can be seen as the

Williams 1027B Open-End Wrench.

[A]1729 5/8x3/4 Open-End Wrenches, Ribbed Style

The next two figures show the alternate (A-prefix) and standard versions of the 1729 model wrench.

Fig. 523 shows

a Williams A1729 5/8x3/4 open-end wrench in the ribbed style,

stamped on the shank with the "Williams U.S.A." logo,

with "Superrench" on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number faintly visible on the back side.

The overall length is 8.2 inches.

The finish is chrome plating,

with extensive losses due to wear,

and the copper underplating can be seen on this example.

Fig. 524 shows

a Williams 1729 5/8x3/4 open-end wrench in the ribbed style,

stamped on the shank with the "Williams U.S.A." logo,

with "Superrench" on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side (not shown).

The overall length is 8.2 inches,

and the finish is chrome plating with polished ribs and faces.

[A]1029 11/16x25/32 Open-End Wrench, Ribbed Style

The next two figures show examples of Williams [A]1029 wrenches in the ribbed style.

Fig. 525 shows

a Williams A1029 11/16x25/32 open-end wrench in the ribbed style,

stamped on the shank with the "Williams U.S.A." logo,

with "Superrench" on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side.

The overall length is 9.0 inches,

and the finish is chrome plating with polished ribs and faces.

Fig. 526 shows

a similar Williams 1029 11/16x25/32 open-end wrench in the ribbed style,

stamped on the shank with the "Williams U.S.A." logo,

with "Superrench" on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side (see upper inset).

The overall length is 9.0 inches,

and the finish is chrome plating with polished ribs and faces.

The 1029 wrench was a popular size,

and earlier examples of this model can be seen as the

Williams Early 1029 Wrench

and

Williams "Chrome Alloy" 1029 Wrench.

A1031B 25/32x13/16 Open-End Wrench, Ribbed-Style

Fig. 527 shows

a Williams A1031B 25/32x13/16 open-end wrench in the ribbed style,

stamped on the shank with the "Williams U.S.A." logo,

with "Superrench" on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side (see upper inset).

The overall length is 9.7 inches.

The finish is chrome plating with polished ribs and faces,

but with some of the copper underplating revealed.

1031 25/32x7/8 Open-End Wrench, Ribbed-Style

Fig. 528 shows

a Williams 1031 25/32x7/8 open-end wrench in the ribbed style,

stamped on the shank with the "Williams U.S.A." logo,

with "Superrench" on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side (see upper inset).

The overall length is 9.7 inches,

and the finish is chrome plating with polished ribs and faces.

A1033A 7/8x15/16 Open-End Wrench, Ribbed-Style

Fig. 529 shows

a Williams A1033A 7/8x15/16 open-end wrench in the ribbed style,

stamped on the shank with the "Williams U.S.A." logo,

with "Superrench" on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side.

The overall length is 10.5 inches,

and the finish is chrome plating,

with minor losses due to rust.

A1733 7/8x1 Open-End Wrench, Ribbed-Style

Fig. 530 shows

a Williams A1733 7/8x1 open-end wrench in the ribbed style,

stamped on the shank with the "Williams U.S.A." logo,

with "Superrench" on the back side.

The faces are stamped with the fractional sizes on the front,

with the model number on the back side (see middle inset).

The overall length is 11.4 inches,

and the finish is chrome plating,

with extensive losses due to rust.

An earlier example of this model can be seen as the

Williams 1733 Wrench.

A1033C 15/16x1 Open-End Wrench, Ribbed-Style

Fig. 531 shows

a Williams A1033C 15/16x1 open-end wrench in the ribbed style,

stamped "Superrench" on the shank.

The faces are stamped with the "Williams U.S.A." logo at one end and the model number at the other,

with the fractional sizes stamped on the back side faces.

The overall length is 11.4 inches,

and the finish is chrome plating with polished ribs and faces.

This example is unusual in that the "Williams U.S.A." logo is stamped on the face,

rather than in the center of the shank.

An earlier example of this model can be seen as the

Williams 1033-C Open-End Wrench,

and a later example is shown as the

Williams 1033-C Flat-Style Open-End Wrench.

1034A 15/16x1-1/16 Open-End Wrench, Ribbed-Style

Fig. 532 shows

a Williams 1034A 15/16x1-1/16 open-end wrench in the ribbed style,

stamped on the shank with the "Williams U.S.A." logo,

with "Superrench" on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side (see upper inset).

The overall length is 11.5 inches,

and the finish is chrome plating with polished ribs and faces.

1035 31/32x1-1/16 Open-End Wrench, Ribbed-Style

Fig. 533 shows

a Williams 1035 31/32x1-1/16 open-end wrench in the ribbed style,

stamped with the "Williams U.S.A." logo on one side,

with the "Superrench" trademark on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side.

The overall length is 11.3 inches,

and the finish is chrome plating with polished ribs and faces.

A1735 1x1-1/8 Open-End Wrench, Ribbed-Style

Fig. 534 shows

a Williams A1735 1x1-1/8 open-end wrench in the ribbed style,

stamped with the "Williams U.S.A." logo on one side,

with the "Superrench" trademark on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side.

The overall length is 12.3 inches,

and the finish is chrome plating with polished ribs and faces.

An earlier example of this model can be seen as the

Williams 1735 Open-End Wrench,

and a later example is shown as the

Williams 1735 Flat-Style Open-End Wrench.

A1037 1-1/16x1-1/4 Open-End Wrench, Ribbed-Style

Fig. 535 shows

a Williams A1037 1-1/16x1-1/4 open-end wrench in the ribbed style,

stamped with the "Williams U.S.A." logo on one side,

with the "Superrench" trademark on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side (see upper inset).

The overall length is 13.2 inches,

and the finish is chrome plating with polished ribs and faces.

A1039C 1-3/8x1-7/16 Open-End Wrench, Ribbed-Style

Fig. 536 shows

a Williams A1039C 1-3/8x1-7/16 open-end wrench in the ribbed style,

stamped with the "Williams U.S.A." logo on one side,

with the "Superrench" trademark on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side.

The overall length is 15.4 inches,

and the finish is chrome plating with polished ribs and faces.

1041 1-7/16x1-5/8 Open-End Wrench, Ribbed-Style

Fig. 537 shows

one of the largest of the ribbed models,

a Williams 1041 1-7/16x1-5/8 open-end wrench in the ribbed style.

The shank is stamped with the "Williams U.S.A." logo on one side,

with the "Superrench" trademark on the back side.

The polished faces are stamped with the fractional sizes on the front,

with the model number on the back side (see upper inset).

The overall length is 16.7 inches,

and the finish is chrome plating with polished ribs and faces.

The Raised-Panel Style

Some time around the mid 1950s Williams adopted a raised-panel style for some of their wrenches,

in particular the box-end and combination wrenches.

This style featured raised panels on both sides of the shank,

with highly polished panel faces and box ends.

The raised-panel style is illustrated in catalog No. 302 from around 1956,

and the same catalog shows open-end wrenches in the "ribbed" style.

(See the 1729 Ribbed Open-End Wrench for an example.)

The raised-panel style was in production for only a relatively brief period

and was soon replaced by the flat-shank style.

(See the later section on the Flat-Shank Superrenches for examples.)

By 1959 the combination wrenches were shown in catalog No. 503 in the new flat-shank style,

and by 1960 the catalog No. 504 was showing the box wrenches with flat shanks as well.

Based on these catalog references,

the manufacturing dates for the raised-panel style are approximately 1954-1958 for combination wrenches

and 1954-1959 for box wrenches.

As might be expected from the short production period,

wrenches in the raised-panel style are relatively uncommon.

7723 3/8x7/16 Box-End Wrench, Raised-Panel Style

Fig. 538 shows

a Williams 7723 3/8x7/16 box-end wrench with raised panels,

stamped with "J.H Williams & Co." and the fractional sizes on the front panel,

with "Superrench" and "U.S.A." on the back side.

The shank is also marked with a forged-in "B" code visible at the left.

The top inset shows a side view of the wrench,

illustrating the flat profile with angled box ends.

The overall length is 7.9 inches,

and the finish is chrome plating.

7725B 1/2x9/16 Box-End Wrench, Raised-Panel Style

Fig. 539 shows

a Williams 7725B 1/2x9/16 box-end wrench with raised panels,

stamped with "J.H Williams & Co." and the fractional sizes on the front panel,

with "Superrench" and "U.S.A." on the back side.

The overall length is 9.2 inches,

and the finish is chrome plating.

The top inset shows a side view of the wrench,

illustrating the flat profile with angled box ends.

7727A 5/8x11/16 Box-End Wrench, Raised-Panel Style

Fig. 540 shows

a Williams 7727A 5/8x11/16 box-end wrench with raised panels,

stamped with "J.H Williams & Co." and the fractional sizes on one side,

with "Superrench" and "U.S.A." on the back side.

The overall length is 10.0 inches,

and the finish is chrome plating.

8729 5/8x3/4 Offset Box-End Wrench, Raised-Panel Style

Fig. 541 shows

a Williams 8729 5/8x3/4 offset box wrench with raised panels,

stamped with "J.H Williams & Co." and the fractional sizes on one side,

with "Superrench" and "U.S.A." on the back side.

The overall length is 10.4 inches.

A faint forged-in code "B" can be seen on the shank at the left.

8029 11/16x25/32 Offset Box-End Wrench, Raised-Panel Style

Fig. 542 shows

a Williams 8029 11/16x25/23 offset box wrench with raised panels,

stamped with "J.H Williams & Co." and the fractional sizes on one side,

with "Superrench" and "U.S.A." on the back side.

The overall length is 11.2 inches,

and the finish is chrome plating.

A forged-in code "B" can be seen on the shank at the left.

8030 11/16x7/8 Offset Box-End Wrench, Raised-Panel Style

Fig. 543 shows

a Williams 8030 11/16x7/8 offset box wrench with raised panels,

stamped with "Superrench" and "U.S.A." on the front panel,

with "J.H Williams & Co." and the fractional sizes on the back side panel.

The overall length is 11.6 inches,

and the finish is chrome plating.

8031 25/32x7/8 Offset Box-End Wrench, Raised-Panel Style

Fig. 544 shows

a Williams 8031 25/32x7/8 offset box wrench in the raised-panel style,

stamped "Superrench" and "U.S.A." on one side,

with "J.H. Williams & Co." and the fractional sizes on the back side panel.

The overall length is 13.2 inches,

and the finish is chrome plating with polished panels and ends.

A forged-in code "B" can be seen on the shank at the left.

8034A 15/16x1-1/16 Offset Box-End Wrench, Raised-Panel Style

Fig. 545 shows

an example of the raised-panel style in a less common size,

a Williams 8034A 15/16x1-1/16 offset box wrench.

The shank is stamped with the "Superrench" trademark plus the model number and "U.S.A" on the raised panel,

with "J.H. Williams & Co." and the fractional sizes on the back side panel.

The back side shank also has a forged-in code "B" (not shown).

The overall length is 15.9 inches,

and the finish is chrome plating with polished panels and ends.

1158 5/16 Combination Wrench, Raised Panel Style

The raised-panel style has been discussed in conjunction with the box-end wrenches,

and we'll now look at some examples of combination wrenches in this style.

Our first example is shown in Fig. 546,

a Williams 1158 5/16 combination wrench stamped "Superrench" and "U.S.A." on the raised panel,

with "J.H. Williams & Co." stamped on the back side.

The overall length is 5.0 inches,

and the finish is chrome plating with polished faces.

The shank has a forged-in "B" code on the back side.

1160 3/8 Combination Wrench, Raised-Panel Style

Fig. 547 shows

a Williams 1160 3/8 combination wrench,

stamped "Superrench" and "U.S.A." on the raised panel,

with "J.H. Williams & Co." on the back side panel.

The shank also has a forged-in code "B" visible at the left.

The overall length is 6.0 inches,

and the finish is chrome plating with polished faces.

1161 7/16 Combination Wrench, Raised-Panel Style

Fig. 548 shows

a Williams 1161 7/16 combination wrench,

stamped "Superrench" and "U.S.A." on the raised panel,

with "J.H. Williams & Co." on the back side panel.

The back side shank also has a forged-in code "B" visible at the left.

The overall length is 6.6 inches,

and the finish is chrome plating with polished faces.

A later version of this model can be seen as the

Williams 1161 Flat-Style Combination Wrench.

1162 1/2 Combination Wrench, Raised-Panel Style

Fig. 549 shows

a Williams 1162 1/2 combination wrench with raised panels,

stamped "J.H. Williams & Co." with the fractional sizes on the front panel,

with "Superrench" and "U.S.A." plus the model number on the back side panel.

The shank also has a forged-in code "II" visible at the left.

The overall length is 7.1 inches,

and the finish is chrome plating,

with losses due to wear.

1163 9/16 Combination Wrench, Raised-Panel Style

Fig. 550 shows

a Williams 1163 9/16 combination wrench,

stamped "Superrench" and "U.S.A." on the raised panel,

with "J.H. Williams & Co." on the back side panel.

The overall length is 7.9 inches,

and the finish is chrome plating with polished faces.

1164 5/8 Combination Wrench, Raised-Panel Style

Fig. 551 shows

a Williams 1164 5/8 combination wrench with raised panels,

stamped "Superrench" and "U.S.A." on the front panel,

with "J.H. Williams & Co." and the fractional sizes on the back side.

The back side shank also has a forged-in code "B" visible at the left.

The overall length is 8.7 inches,

and the finish is chrome plating with polished faces.

An earlier version of this model can be seen as the

Williams 1164 Oval-Shank Combination Wrench,

and a later version can be seen as the

Williams 1164 Flat-Style Combination Wrench.

1166 3/4 Combination Wrench, Raised-Panel Style

Fig. 552 shows

a Williams 1166 3/4 combination wrench with raised panels,

stamped "Superrench" and "U.S.A." on the front panel,

with "J.H. Williams & Co." and the fractional sizes on the back side.

The back side shank also has a forged-in code "B" faintly visible at the left.

The overall length is 10.6 inches,

and the finish is chrome plating with polished faces.

1176 1-7/16 Combination Wrench, Raised-Panel Style

Fig. 553 shows

a much larger example of the paneled style,

a Williams 1176 1-7/16 combination wrench.

The panels are stamped "Superrench" and U.S.A." on the front,

with "J.H. Williams & Co." and the fractional size on the back side.

The back side shank also has a forged-in code "B" (not shown).

The overall length is 21.2 inches,

and the finish is chrome plating with polished faces.

Flat-Shank Superrenches

The last major change in Williams' wrench styles came in 1959 with the introduction

of the now familiar style with flat shanks.

The flat-shank style was used for all of the major lines of wrenches —

open-end, box-end, and combination —

and for the first time all of these major wrench types had consistent markings.

The markings were changed considerably for the flat-shank style.

The Williams name retained its underline from the final "S" and was enclosed by an outline box,

then bracketed by sets of three parallel lines.

The Superrench trademark (when present) was similarly enclosed in an outline box bracketed by lines

and appeared on the opposite side from the company name.

The model number and "U.S.A." (or opening sizes) were placed at the ends of the line markings.

Smaller wrenches were given variant markings with the outline box omitted and fewer bracketing lines.

The flat-shank style was first introduced in 1959 for the open-end and combination wrenches,

which are shown in the new style in catalog No. 503 of that year.

By 1960 the flat-shank style had been extended to the other wrench types as well,

and the illustrations in catalog No. 504 of 1960 all show the new style.

The flat-shank style remained in production for many years,

until at least the mid 1990s.

1723 3/8x7/16 Open-End Wrench, Flat-Shank Style

Fig. 554 shows

an example of the flat shank style for a Williams 1723 3/8x7/16 open-end wrench.

The Williams name appears underlined and is enclosed in an outline box,

and the "Superrench" trademark is outlined on the back side.

The shank also has a forged-in "B" code visible at the left.

The overall length is 4.6 inches,

and the finish is chrome plating with polished faces.

1029 11/16x25/32 Open-End Wrench, Flat-Shank Style

Fig. 555 shows

another example of the flat shank style,

a Williams 1029 11/16x25/32 open-end wrench.

The Williams name appears underlined and is enclosed in an outline box,

and the "Superrench" trademark is outlined on the back side.

The shank also has a forged-in "B" code visible at the left.

The overall length is 9.0 inches,

and the finish is chrome plating with polished faces.

An earlier version of this model can be seen as the

Williams 1029 Open-End Wrench.

1731A 3/4x7/8 Open-End Wrench, Flat-Shank Style

Fig. 556 shows

a Williams 1731A 3/4x7/8 open-end wrench,

stamped with the Williams underline logo in an outline box,

with "Superrench" and "U.S.A." on the back side.

The shank also has a forged-in "B" code visible at the left.

The overall length is 9.7 inches,

and the finish is chrome plating with polished faces.

1033C 15/16x1 Open-End Wrench, Flat-Shank Style

Fig. 557 shows

a Williams 1033C 15/16x1 open-end wrench,

stamped with the Williams underline logo in an outline box,

with "Superrench" and "U.S.A." on the back side.

The shank also has a forged-in "B" code visible at the left.

The overall length is 11.3 inches,

and the finish is chrome plating,

with some losses due to rust.

1735 1x1-1/8 Open-End Wrench, Flat-Shank Style

Fig. 558 shows

a Williams 1735 1x1-1/8 open-end wrench,

stamped with the Williams underline logo in an outline box,

with "Superrench" and "U.S.A." on the back side.

The shank also has a forged-in "O" code visible at the left.

The overall length is 12.2 inches,

and the finish is chrome plating with polished faces.

1090 7/16x1/2 Tappet Wrench, Flat-Shank Style

The next three figures show examples of tappet wrenches in the flat-shank style.

Fig. 559 shows

a Williams 1090 7/16x1/2 tappet wrench,

marked with the standard flat-shank logo,

and with a forged "B" code at the left.

The overall length is 8.0 inches,

and the finish is chrome plating with polished faces.

1096 15/16x1 Tappet Wrench, Flat-Shank Style

Fig. 560 shows

an example of a tappet wrench in the flat-shank style,

a Williams 1096 15/16x1 tappet wrench marked with the standard flat-shank logo,

and with a forged-in "B" code at the left.

The overall length is 9.0 inches,

and the finish is chrome plating with polished faces.

1096H 7/8x1-1/16 Tappet Wrench, Flat-Shank Style

Fig. 561 shows

another example of a flat-shank style tappet wrench,

a Williams 1096H 7/8x1-1/16 wrench marked with the standard flat-shank logo,

and with a forged-in "O" code at the right.

The overall length is 9.0 inches,

and the finish is chrome plating with polished faces.

Ignition Wrenches

The flat-shank style was also extended to the miniature open-end ignition wrenches,

as the next several figures will show.

As before,

two styles of ignition wrenches were available, one modeled as a miniature open-end wrench in an 1106-1109 series,

and the other as a miniature angle-head obstruction wrench in an 1112-1136 series.

The design of the latter type is slightly different from their earlier counterparts,

as the offset angles appear to match the 15 and 65 degree angles used for modern angle-head wrenches.

(Earlier ignition wrenches had a more steeply offset opening.)

Examples of ignition wrenches in the earlier era can be seen in the section on

Ignition "Superrenches".

1108A 1/4x5/16 Ignition Wrench, Flat-Shank Style

Fig. 562 shows

a Williams 1108A 1/4x5/16 ignition wrench,

marked with a variant of the standard flat-shank logo.

The overall length is 3.5 inches,

and the finish is chrome plating with polished faces.

1122 11/32x11/32 Ignition Wrench, Flat-Shank Style

Fig. 563 shows

a Williams 1122 11/32x11/32 ignition wrench,

marked with a variant of the standard flat-shank logo.

The overall length is 3.8 inches,

and the finish is chrome plating with polished faces.

1132 1/2x1/2 Ignition Wrench, Flat-Shank Style

Fig. 564 shows

a Williams 1132 1/2x1/2 ignition wrench,

marked with the standard flat-shank logo.

The overall length is 4.5 inches,

and the finish is chrome plating with polished faces.

7727A 5/8x11/16 Box-End Wrench, Flat-Shank Style

Fig. 565 shows

an example of a box wrench in the flat-shank style,

a Williams 7727A 5/8x11/16 box wrench marked with the Williams logo,

with "Superrench" and "U.S.A." on the back side.

A forged-in "B" code is visible at the left of the shank.

The overall length is 10.0 inches.

The wrench is finished with satin chrome plating on the shank with polished ends.

7731A 3/4x7/8 Box-End Wrench, Flat-Shank Style

Fig. 566 shows

a Williams 7731A 3/4x7/8 box wrench in the flat-shank style,

stamped with the Williams scroll logo and fractional sizes on the front,

with "Superrench" and "U.S.A." on the back side.

The overall length is 12.3 inches,

and the finish is satin chrome plating with polished ends.

7733 7/8x1 Box-End Wrench, Flat-Shank Style

Fig. 567 shows

a Williams 7733 7/8x1 box wrench in the flat-shank style,

stamped with the Williams logo,

with "Superrench" and "U.S.A." on the back side.

The overall length is 14.2 inches,

and the finish is chrome plating with polished ends.

7033C 15/16x1 Box-End Wrench, Flat-Shank Style

Fig. 568 shows

a Williams 7033C 15/16x1 box wrench in the flat-shank style,

stamped with the Williams logo and fractional sizes,

with "Superrench" and "U.S.A." on the back side.

The overall length is 14.8 inches,

and the finish is chrome plating with polished ends.

8029B 11/16x3/4 Offset Box-End Wrench, Flat-Style Shank

Fig. 569 shows

an example of an offset box wrench in the flat style,

a Williams 8029B 11/16x3/4 offset box wrench.

The shank is stamped with the Williams logo and fractional sizes on one side,

with "Superrench" and "U.S.A." on the back side.

The overall length is 10.8 inches,

and the finish is chrome plating with polished ends.

An earlier generation of this model can be seen as the

Williams 8029B Offset Box Wrench.

8033C 15/16x1 Offset Box-End Wrench, Flat-Style Shank

Fig. 570 shows

a Williams 8033C 15/16x1 offset box wrench,

stamped with the Williams logo and fractional sizes on one side,

with "Superrench" and "U.S.A." on the back side.

A forged-in code "B" can be seen on the shank at the right.

The overall length is 14.7 inches,

and the finish is chrome plating with polished ends.

8037A 1-1/8x1-5/16 Offset Box-End Wrench, Flat-Style Shank

Fig. 571 shows

a Williams 8037A 1-1/8x1-5/16 offset box wrench with

the standard flat-style markings.

The back side shank also has a forged-in code "B" (not shown).

The overall length is 18.3 inches,

and the finish is chrome plating with polished ends.

1161 7/16 Combination Wrench, Flat-Shank Style

Fig. 572 shows

a Williams 1161 7/16 combination wrench in the flat-shank style,

stamped "Superrench" and "U.S.A." on one side,

with "Williams" and the fractional sizes on the back side.

The overall length is 6.6 inches,

and the finish is chrome plating with polished faces.

A forged-in code "B" can be seen on the shank at the left.

An earlier version of this model can be seen as the

Williams 1161 Paneled Combination Wrench.

1164 5/8 Combination Wrench, Flat-Shank Style

Fig. 573 shows

a Williams 1164 5/8 combination wrench in the flat-shank style,

stamped "Williams" with the fractional sizes on the shank,

and with "Superrench" and "U.S.A." on the back side.

The shank also has a forged-in "B" code visible at the left.

The overall length is 8.7 inches,

and the finish is chrome plating with polished faces.

An earlier version of this model can be seen as the

Williams 1164 Paneled Combination Wrench.

1165 11/16 Combination Wrench, Flat-Shank Style

Fig. 574 shows

a Williams 1165 11/16 combination wrench in the flat-shank style,

stamped "Williams" with the fractional sizes on the shank,

and with "Superrench" and "U.S.A." on the back side.

The shank also has a forged-in "B" code visible at the left.

The overall length is 9.6 inches,

and the finish is chrome plating with polished faces.

XOEE-1218 9/16 Short Combination Wrench, Flat-Shank Style

In later years Williams offered an XOEE series of short combination wrenches.

Fig. 575 shows

a Williams XOEE-1218 9/16 short combination wrench,

stamped "Superrench" and "U.S.A." on the shank,

with "Williams" and the fractional sizes on the back side.

The back side shank also has a forged-in code "O" visible at the left.

The overall length is 5.5 inches,

and the finish is chrome plating with polished faces.

XOEE-1220 5/8 Short Combination Wrench, Flat-Shank Style

Fig. 576 shows

a Williams XOEE-1220 5/8 short combination wrench,

stamped "Superrench" and "U.S.A." on the shank,

with "Williams" and the fractional sizes on the back side.

The back side shank also has a forged-in code "O" (not shown).

The overall length is 5.9 inches,

and the finish is chrome plating with polished faces.

Industrial Finish Wrenches

729 5/8x3/4 Open-End Wrench, Flat-Shank Style

Fig. 577 shows

a later Williams 729 5/8x3/4 open-end wrench,

stamped with "Williams" and "U.S.A." on the shank,

with "Williams" and the fractional sizes on the back side.

The back side shank also has a forged-in code "B" visible at the left.

The overall length is 8.2 inches,

and the finish is black oxide.

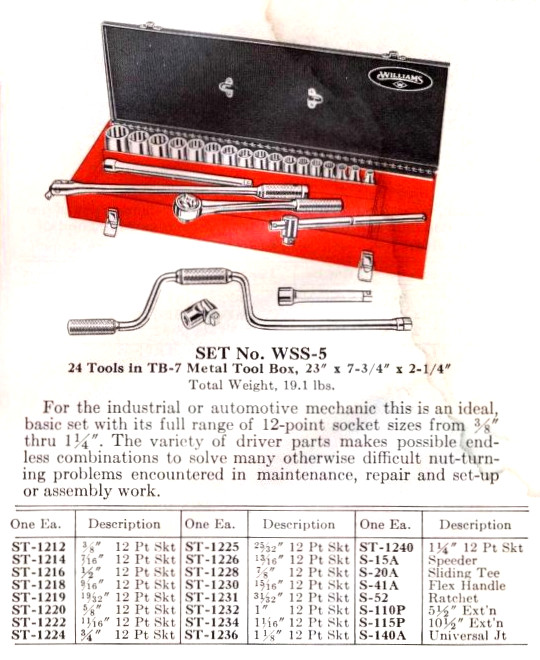

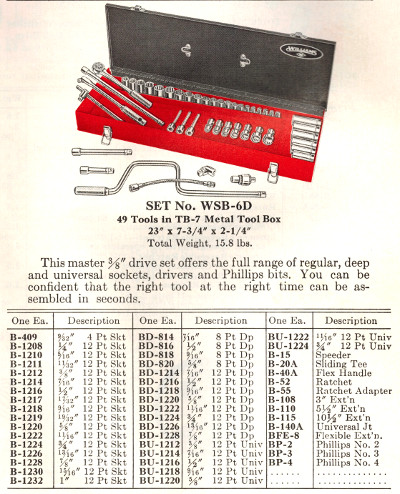

Later Sockets and Drive Tools

In this section we'll look at the later production of sockets and drive tools,

roughly from the 1960s onward.

In the late 1960s or early 1970s Williams updated its socket set model numbers again,

this time giving them a "WS" prefix followed immediately by the drive size prefix.

For example,

3/8-drive sets formed the "WSB" series, and 1/4-drive sets formed the "WSM" series.

Our first reference for these sets is the Williams catalog No. 307,

undated but from around 1970.